CÉLULAS COMPACTAS DE PALETIZADO

Hablamos de una solución económica que se ajusta a la mayoría de las aplicaciones. Paletizado de cajas de hasta 20 kg y producciones de hasta 15 cajas/minuto.

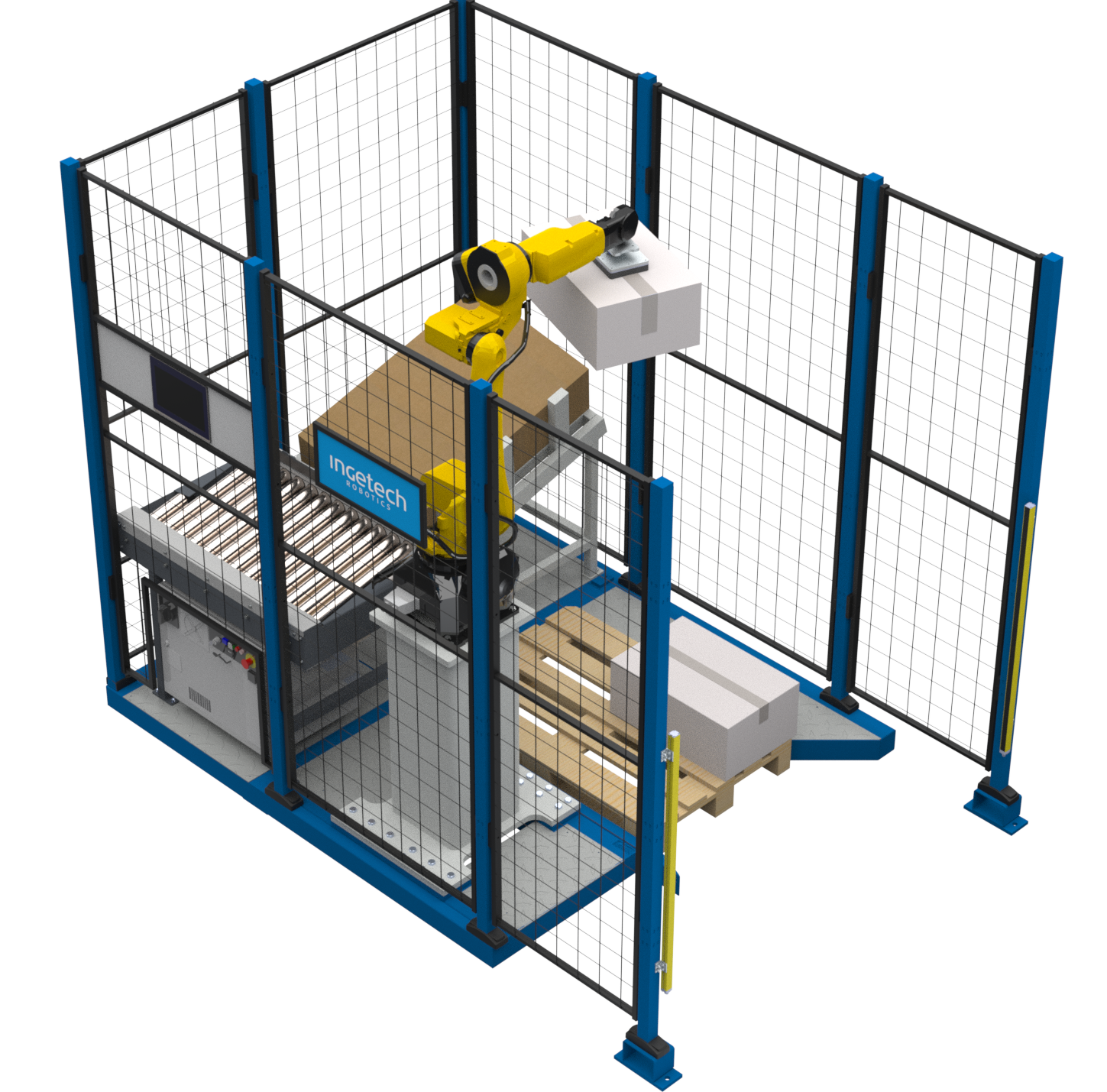

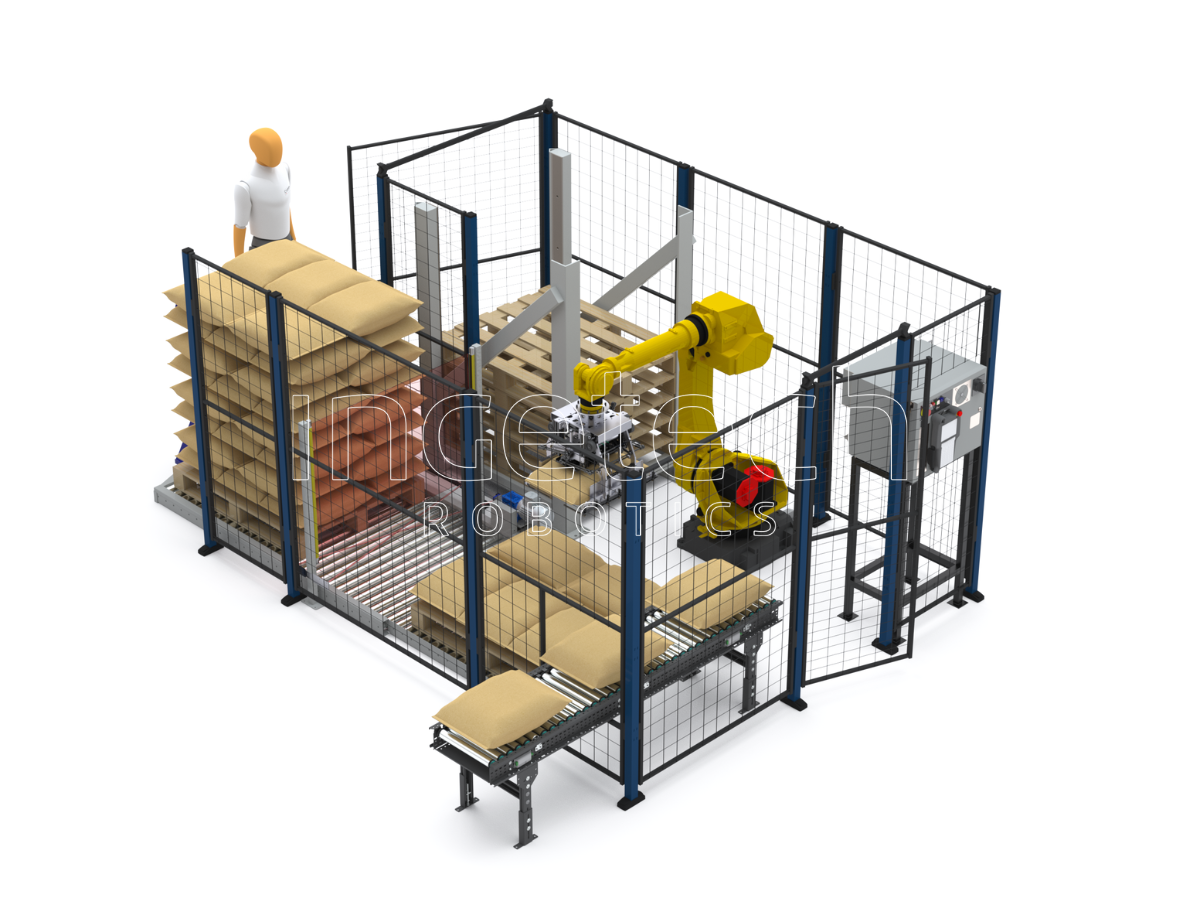

Nuestras células compactas de paletizado por robot son la mejor solución cuando se trata de instalar un paletizador económico y con mínimo espacio en planta.

Las células están diseñadas bajo el concepto «PLUG & PLAY» lo que le permite unas instalación en tiempo record. El conjunto de sus componentes está montado subre una plataforma transportable por carretilla elevadora.

Las células compactas de paletizado de INGETECH ROBOTICS, están preparadas para la Industria 4.0. La incorporación del módulo KIT ASSIST permite la asistencia en remoto para resolución de incidencias, actualización de software, programación de nuevos mosaicos, monitorización en tiempo real, etc.

CÉLULAS COMPACTAS DE PALETIZADO PARA CAJAS

CÉLULAS PLUG & PLAY

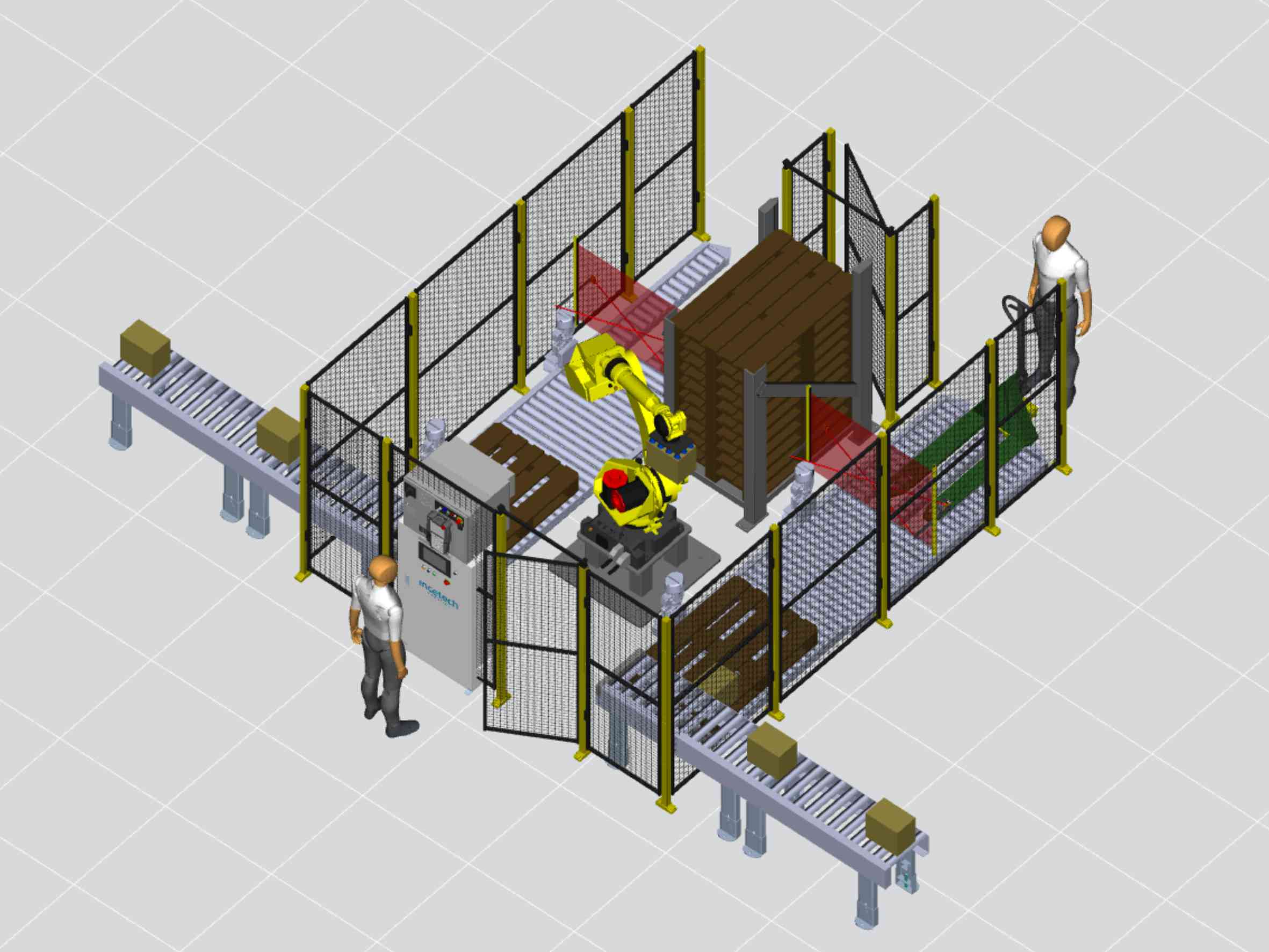

CÉLULA DE PALETIZADO

IR-PAL1

NÚMERO DE LÍNEAS

1

NÚMERO DE PALÉS

1

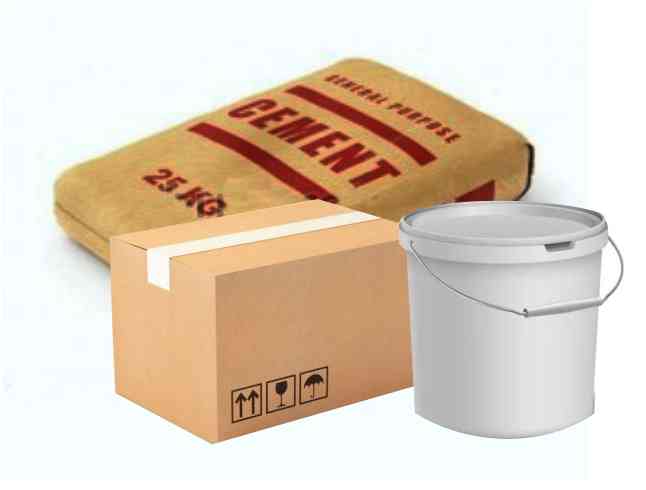

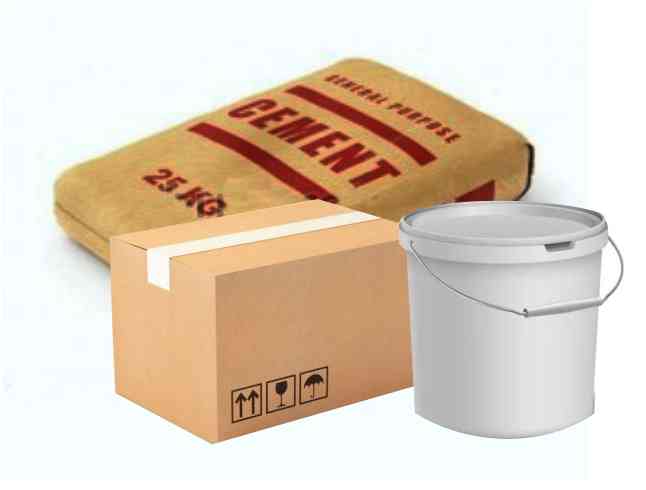

TIPO DE PRODUCTOS

Cajas

PESO MÁXIMO UD.

23 Kg

UNIDADES / MIN

< 15

EXTRACCIÓN PALÉS

Manual

La célula de paletizado IR-PAL1 es la solución más económica para paletizado por robot.

Está preparada para el paletizado de cajas, y paletizado de sacos de una única línea de transporte sobre palé europeo EPAL y americano.

De fácil transporte e instalación, puede estar funcionando en 1 día.

CARACTERÍSTICAS IR-PAL.1

| PICKING | Unitario |

| PESO CAJAS (SEGÚN ROBOT) | <23 Kg |

| VELOCIDAD DE TRABAJO | 15 cajas/min |

| SISTEMA PALETIZADO | 1 Palé |

| INSTALACIÓN | PLUG & PLAY |

| MÍNIMO ESPACIO EN PLANTA | 4,23 m2 |

| TRANSPORTE COMPONENTES | EN BLOQUE |

CÉLULA DE PALETIZADO

IR-PAL2

NÚMERO DE LÍNEAS

1

NÚMERO DE PALÉS

2

TIPO DE PRODUCTOS

Cajas

PESO MÁXIMO UD.

32 Kg

UNIDADES / MIN

< 15

EXTRACCIÓN PALÉS

Manual

La célula de paletizado IR-PAL2 es una solución de paletizado para 2 posiciones de palé, tanto europeo como americano.

Permite asimismo mediante la opción SCW (safe continuous work), cargar palé vacío o retirar palé lleno sin pérdidas de tiempo ni de producción, ya que la célula sigue trabajando con todos sus sistemas de seguridad activos.

El concepto de transporte e instalación de estas células compactas de paletizado es el mismo de la IR-PAL1 Plug & Play.

Puesa en marcha en 1 día.

CARACTERÍSTICAS

| PICKING | Unitario |

| PESO CAJAS (SEGÚN ROBOT) | <32 Kg |

| VELOCIDAD DE TRABAJO | 15 cajas/min |

| SISTEMA PALETIZADO | 2 Palés simultáneos o alternos |

| OPCIONES | Sistema SCW (Safe Continuous Work). Carga y retirada de palé sin paradas. Cartones intermedios o Interlayers |

| INSTALACIÓN | PLUG & PLAY |

| MÍNIMO ESPACIO EN PLANTA | 7,59 m2 |

| TRANSPORTES COMPONENTES | EN BLOQUE |

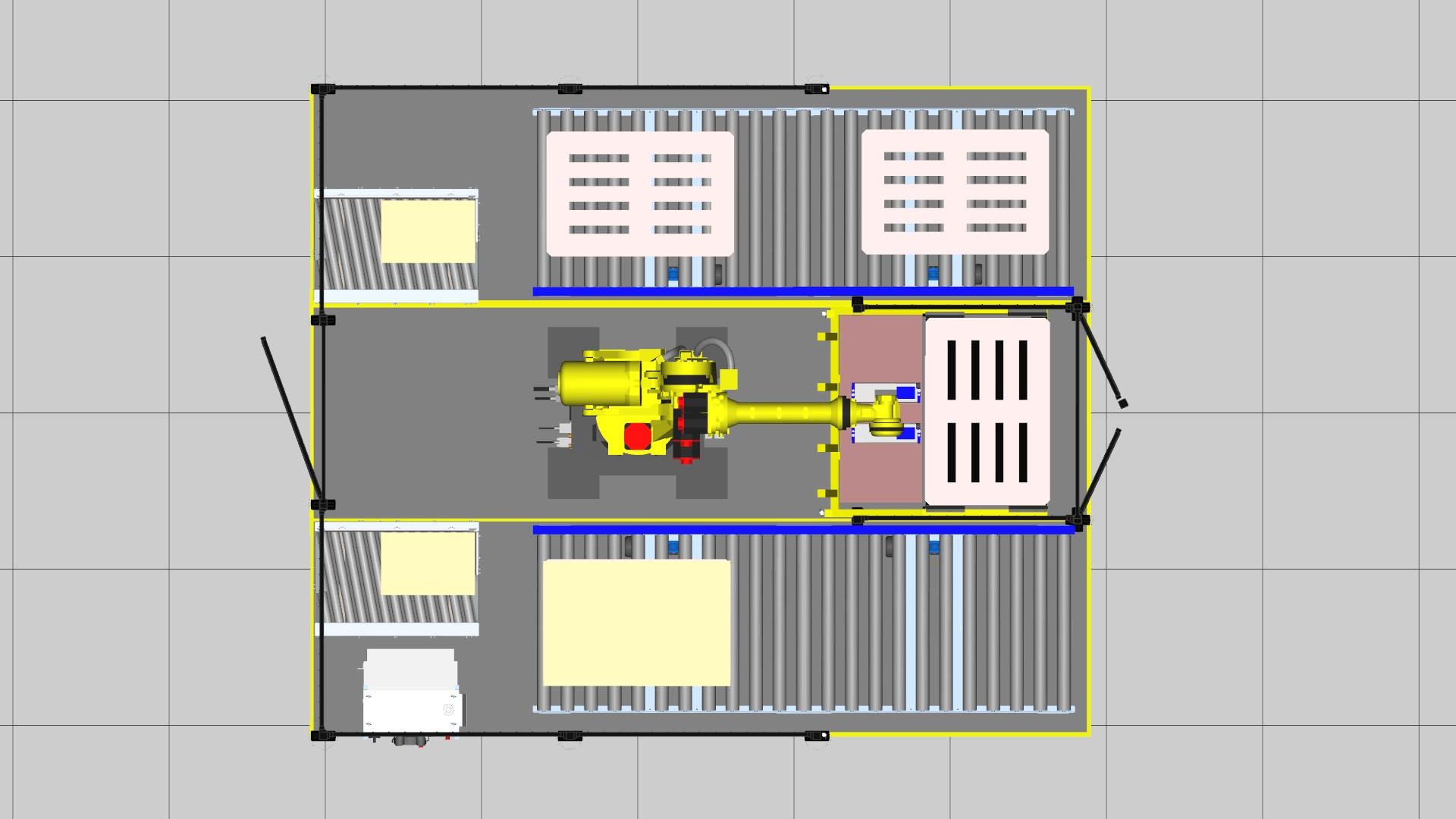

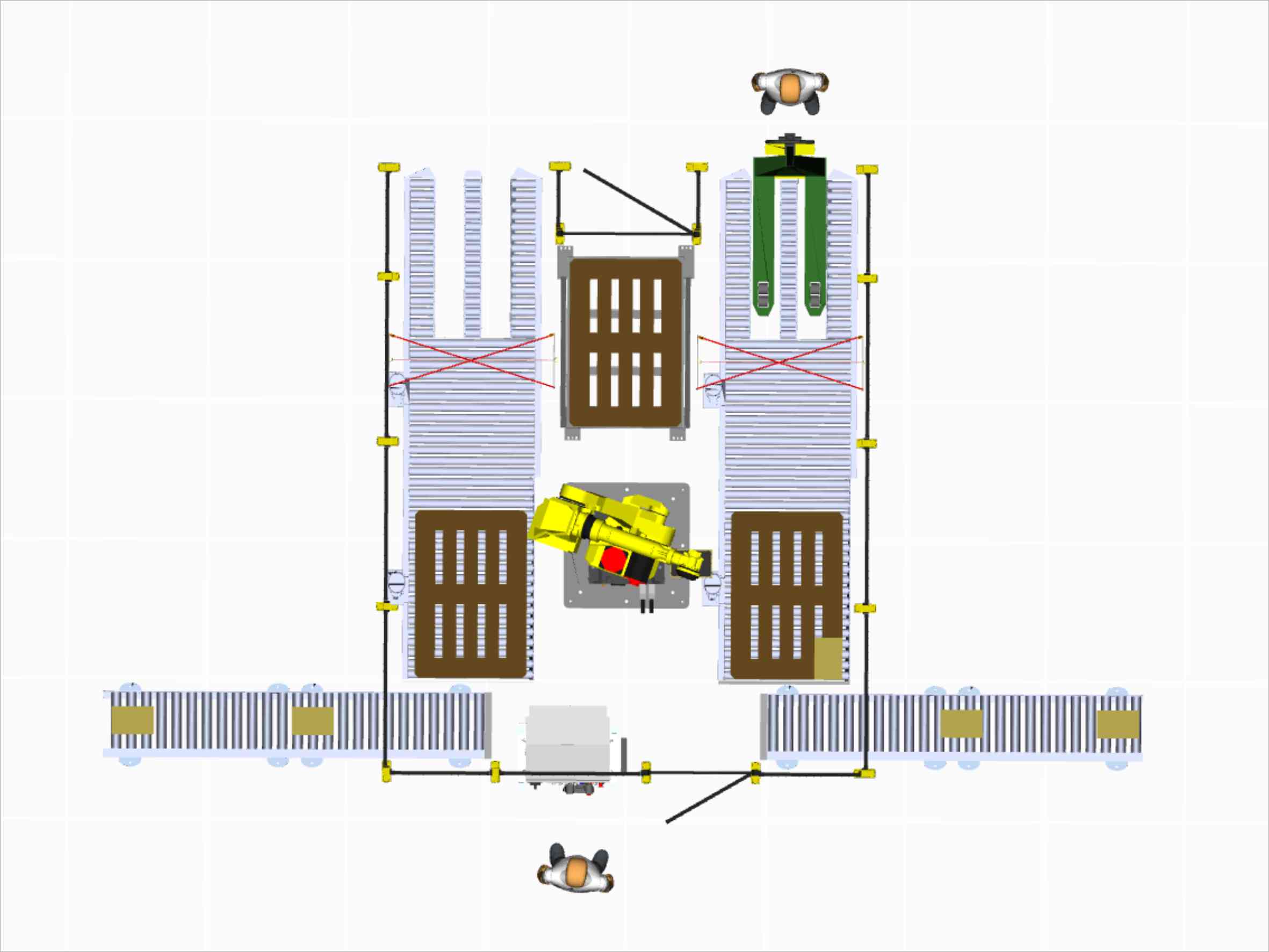

CÉLULA DE PALETIZADO

IR-PAL3 Modupal

NÚMERO DE LÍNEAS

2

NÚMERO DE PALÉS

2

TIPO DE PRODUCTOS

Cajas, Sacos, Cubos.

PESO MÁXIMO UD.

150 Kg

UNIDADES / MIN

< 10

EXTRACCIÓN PALÉS

Automática

La célula de paletizado IR-PAL3 ModuPal es una solución de paletizado para 2 posiciones de palé, tanto europeo como americano.

Se trata de un concepto de célula modular compuesta de 2 tipos de módulos de tamaño compacto.

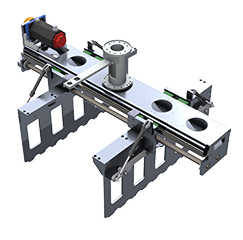

· Módulo de ROBOT: que incluye el robot, y 1 almacén de palés e interfaldas o cartones intermedios.

· Módulo de TRANSPORTE: que incorpora 1 transportador alineador de cajas y 2 transportadores de palés, 1 de carga, y 1 de extracción que permite dar continuidad a la célula aunque no se haya retirado el palé paletizado previamente.

Los módulos se conectan entre si de manera tanto mecánica como eléctrica y permiten su ampliación de manera sencilla y fácil cuando la producción aumente. Pueden incorporar 1 transportador formador de mosaicos previo para la paletización de capas enteras.

El paletizado se realiza sin pérdidas de tiempo ni de producción, ya que es el robot el que alimenta los palés a la célula que sigue trabajando con una autonomía aumentada.

CARACTERÍSTICAS

| PICKING | Unitario |

| PESO CAJAS (SEGÚN ROBOT) | <150 Kg |

| VELOCIDAD DE TRABAJO | 10 cajas/min (picking unitario) |

| SISTEMA PALETIZADO | 2 Palés simultáneos o alternos |

| OPCIONES | Módulos supletorios. |

| INSTALACIÓN | PLUG & PLAY |

| MÍNIMO ESPACIO EN PLANTA | 7 m2 x módulo |

| TRANSPORTES COMPONENTES | En módulos |

CÉLULAS COMPACTAS DE PALETIZADO PARA CAJAS

CÉLULAS DE MONTAJE RÁPIDO

CÉLULA DE PALETIZADO

IR-PAL4.1

NÚMERO DE LÍNEAS

1

NÚMERO DE PALÉS

1

TIPO DE PRODUCTOS

Cajas, Sacos, Cubos.

PESO MÁXIMO UD.

150 Kg

UNIDADES x MIN

< 12

EXTRACCIÓN PALÉS

Automática

La célula de paletizado IR-PAL4 es una solución de paletizado para 1 posición de palé, tanto europeo como americano.

Se trata de un concepto de célula modular completamente automática.

Incorpora:

- Transportador alimentador con buffer de acumulación sin presión.

- Almacén de palés vacíos de hasta 15 unidades.

- Posicionado del Palé a formar mediante la garra del robot.

- Paletizado sobre camino de rodillos y extracción sin paradas.

- Tridente de extracción de rodillos para retirada por carretilla o transpaleta.

El paletizado se realiza sin pérdidas de tiempo ni de producción, ya que es el robot el que alimenta los palés a la posición de paletizado mientras el sistema de transporte evacúa el palé formado. La célula sigue trabajando con una autonomía aumentada.

CARACTERÍSTICAS

| PICKING | Unitario o por grupos |

| PESO PRODUCTO (SEGÚN ROBOT) | <150 Kg |

| VELOCIDAD DE TRABAJO | 12 Ud/min (picking unitario) |

| SISTEMA PALETIZADO | 1 Palé |

| INSTALACIÓN | PLUG & PLAY |

| MÍNIMO ESPACIO EN PLANTA | 12 m2 Aprox |

CÉLULA DE PALETIZADO

IR-PAL4.2

NÚMERO DE LÍNEAS

2

NÚMERO DE PALÉS

2

TIPO DE PRODUCTOS

Cajas, Sacos, Cubos.

PESO MÁXIMO UD.

150 Kg

UNIDADES x MIN

< 10

EXTRACCIÓN PALÉS

Automática

La célula de paletizado IR-PAL 4.2 es una solución de paletizado para 2 posiciones de palé, tanto europeo como americano.

Se trata de un concepto de célula con capacidad de paletizar todo tipo de productos, a la vez que se autoabastece del almacén de palés de manera automática.

Las células compactas de paletizado IR-PAL 4.2 incorporan:

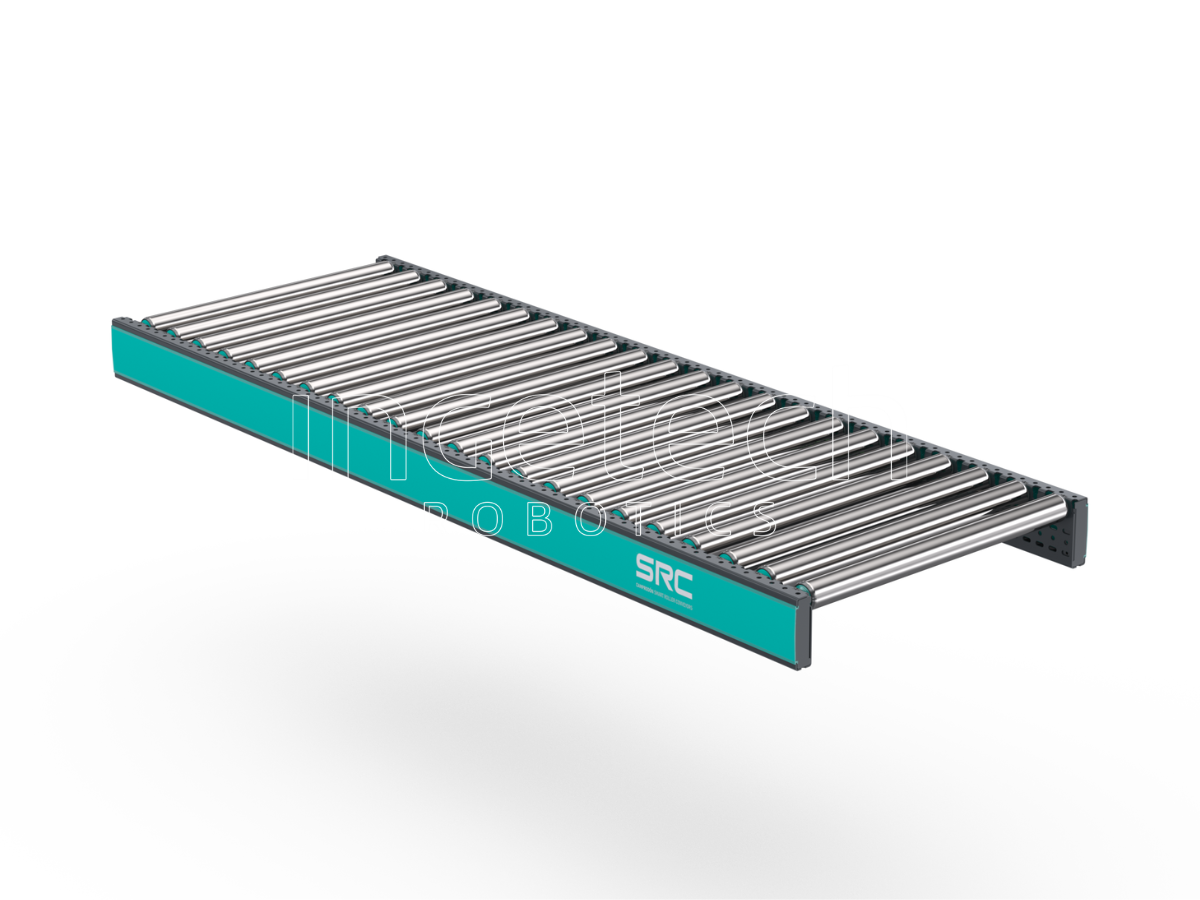

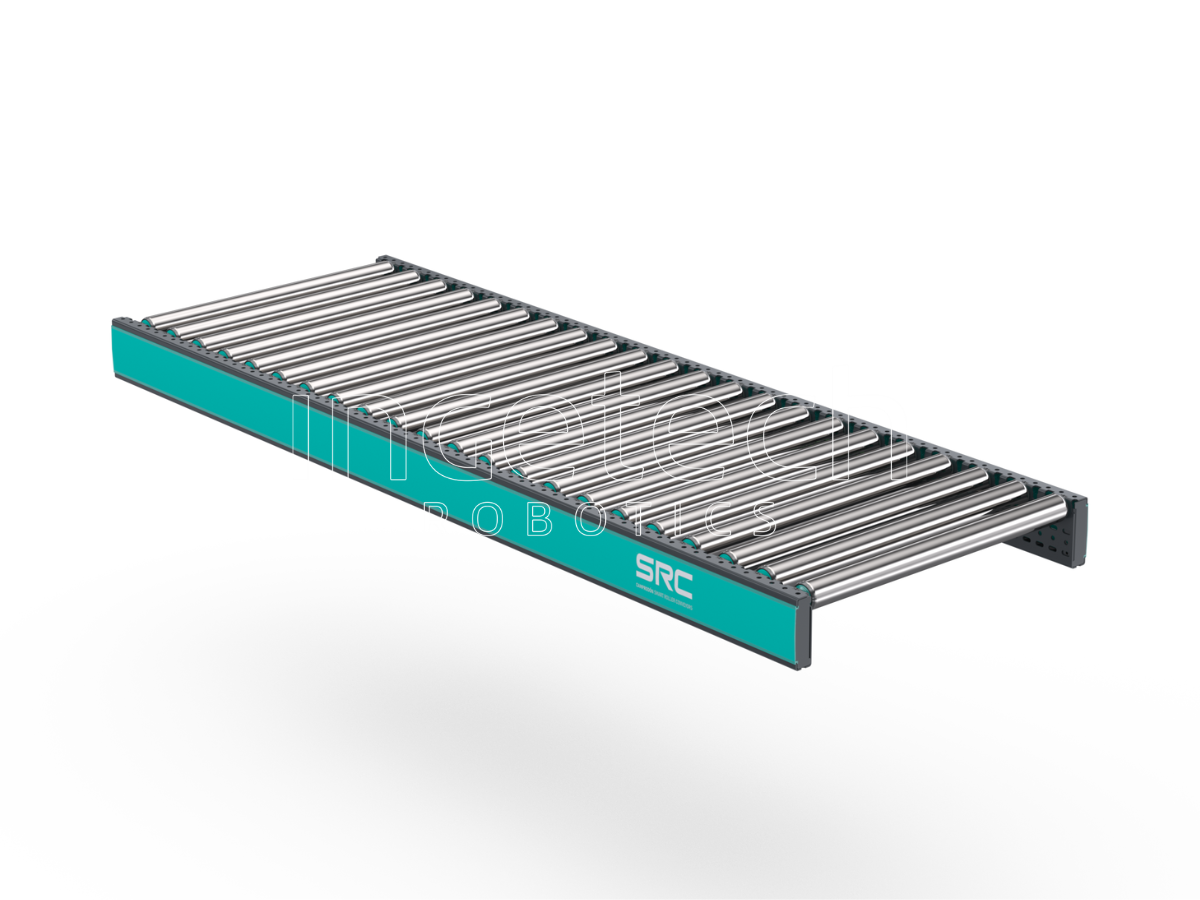

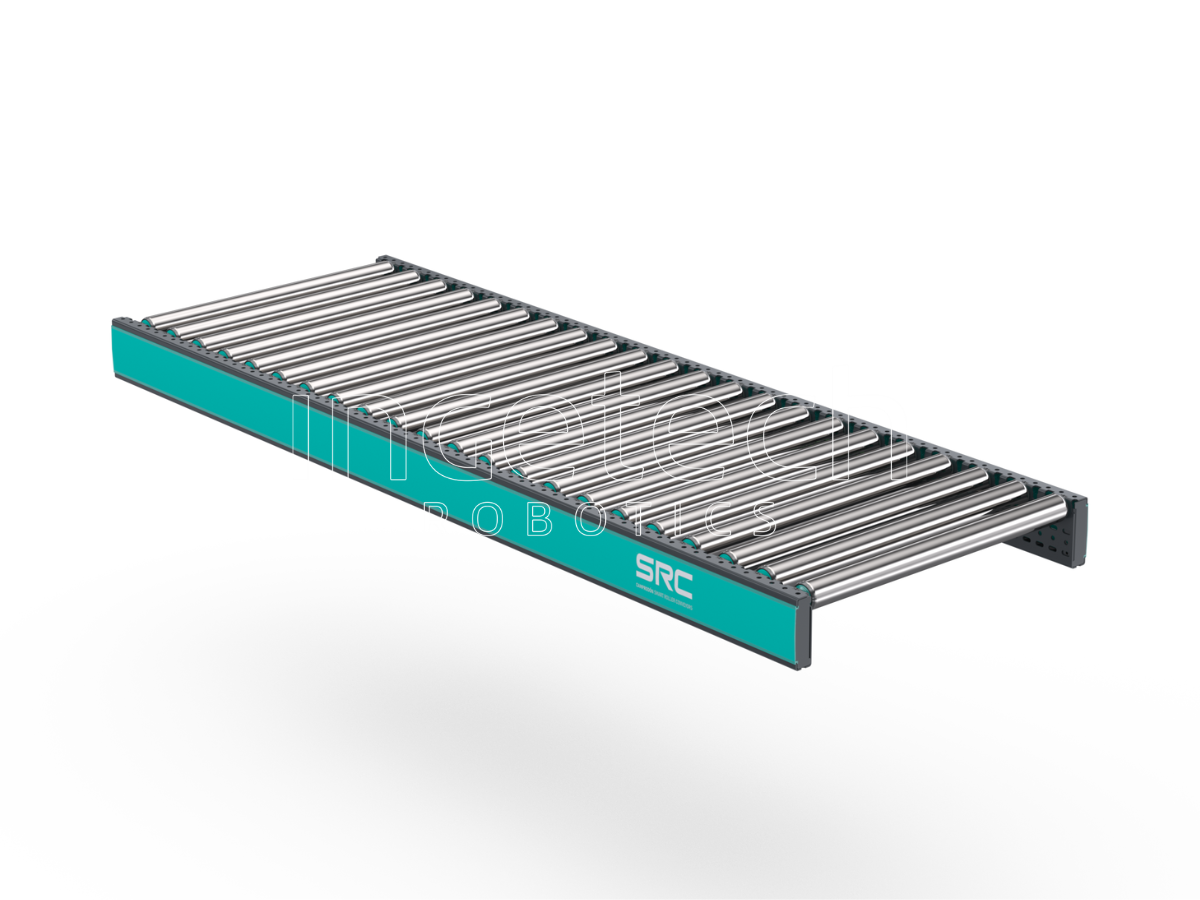

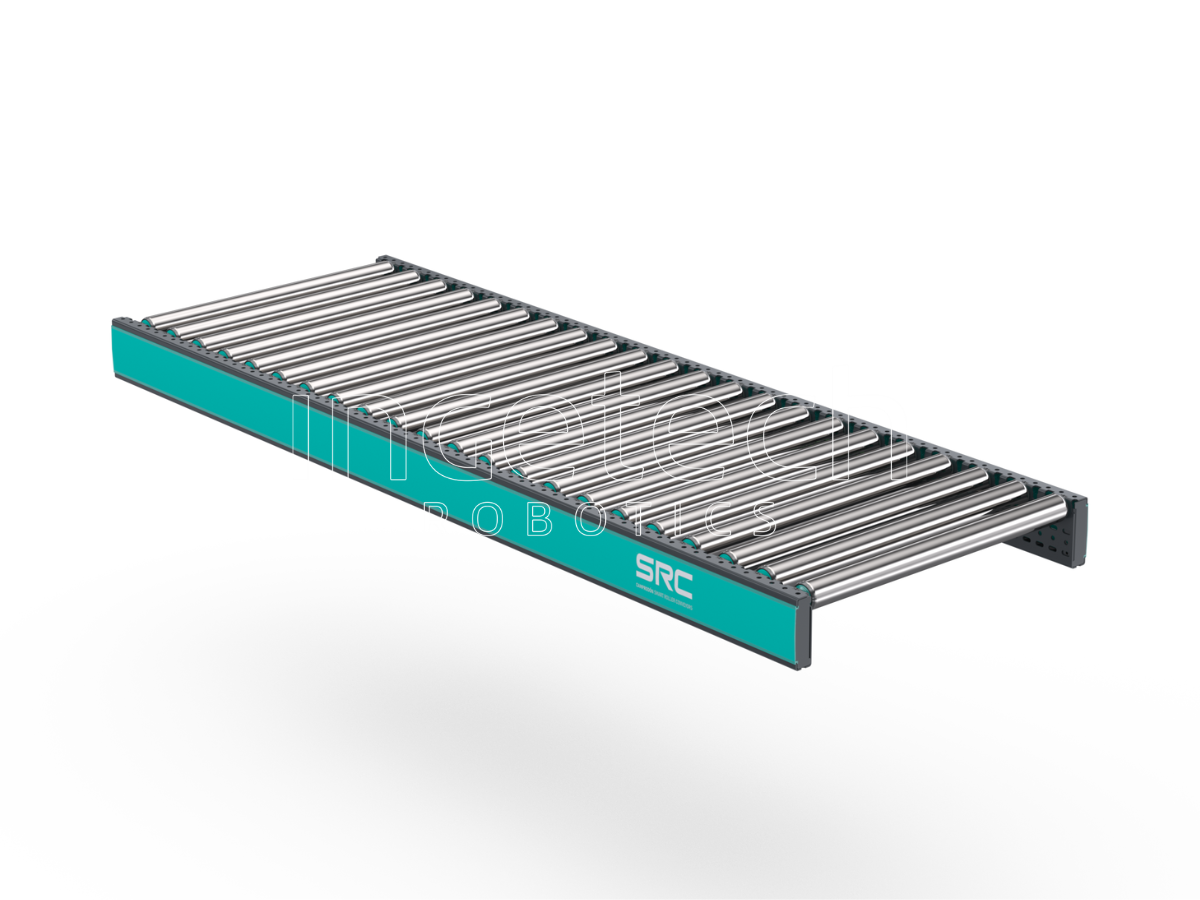

- 2 Transportadores de rodillos con posibilidad de buffer de acumulación

- Almacén de palés vacíos de hasta 15 unidades.

- El propio robot coloca los palés vacíos en su posición de paletizado.

- Paletizado sobre camino de rodillos de perfil bajo.

- Tridente de extracción de rodillos para retirada de palés llenos tanto por carretilla como por transpaleta manual.

El paletizado se realiza sin pérdidas de tiempo ni de producción, ya que es el robot el que alimenta los palés a la posición de paletizado mientras el sistema de transporte evacúa el palé formado. La célula sigue trabajando con una autonomía aumentada.

CARACTERÍSTICAS

| PICKING | Unitario o por grupos |

| PESO PRODUCTO (SEGÚN ROBOT) | hasta 150 Kg |

| VELOCIDAD DE TRABAJO | 12 Ud/min (picking unitario) |

| SISTEMA PALETIZADO | 2 Palé |

| INSTALACIÓN | PLUG & PLAY |

| MÍNIMO ESPACIO EN PLANTA | 12 m2 aprox. |

EJEMPLOS DE APLICACIONES DE LAS CÉLULAS COMPACTAS DE PALETIZADO

PALETIZADO DE CAJAS DE BOTELLAS DE VINO

CAJAS ESTÁNDAR DE 6 y 12 BOTELLAS

PRODUCTO PALETIZADO

Caja cartón de 6 ud 8 Kg

Caja cartón de 12 ud 16 Kg

TIPO DE PALÉ

800 x 1.200 mm

INTERFALDA

700 x 1.100 mm

PESO DEL PRODUCTO

Kg

PRODUCCIÓN

Nº Cajas x hora

MONTAJE Y PUESTA EN MARCHA DE LAS CÉLULAS COMPACTAS DE PALETIZADO

Nuestras células compactas de paletizado han sido diseñadas con el concepto PLUG & PLAY para un montaje rápido y seguro.

Su instalación no interfiere en su producción. Usted podrá seguir trabajando durante el montaje de la célula, y en 1 sólo día la tendrá instalada. Sólo necesita disponer de una carretilla elevadora para su ubicación. Nada más sencillo y rápido.

Un entorno amigable en las pantallas de operación, le facilitarán asimismo su puesta en marcha de manera que el mismo día estará usted paletizando con su robot.

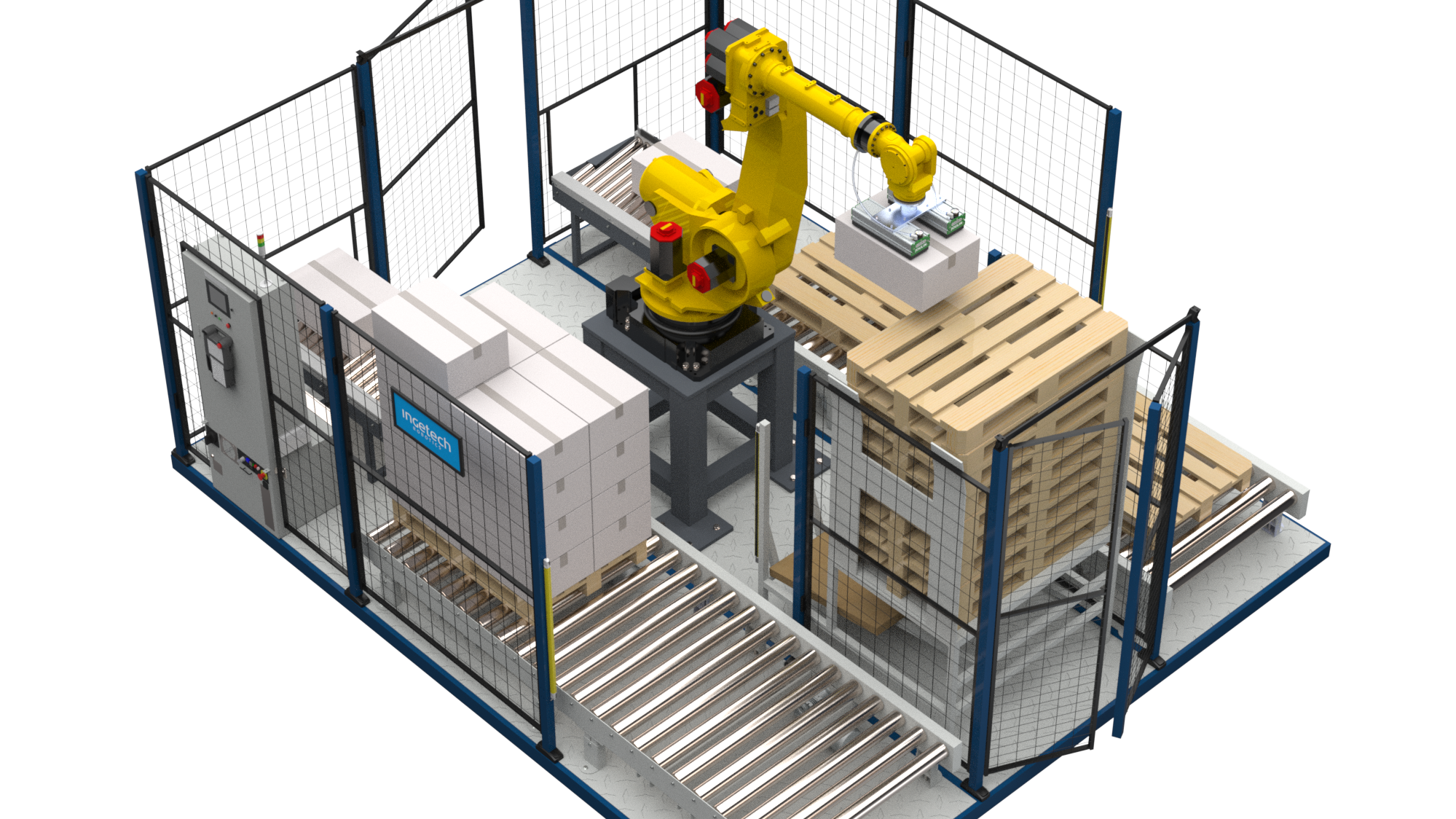

OTRAS SOLUCIONES DE PALETIZADO CON ROBOT

Células de paletizado para altas producciones o cargas pesadas >20 Kg/unidad.

Se trata de células con robots de mayor tamaño y que pueden realizar pickings unitarios, de varias cajas a la vez, de filas completas, o de capas completas. Su diseño se realiza ajustado a la aplicación.

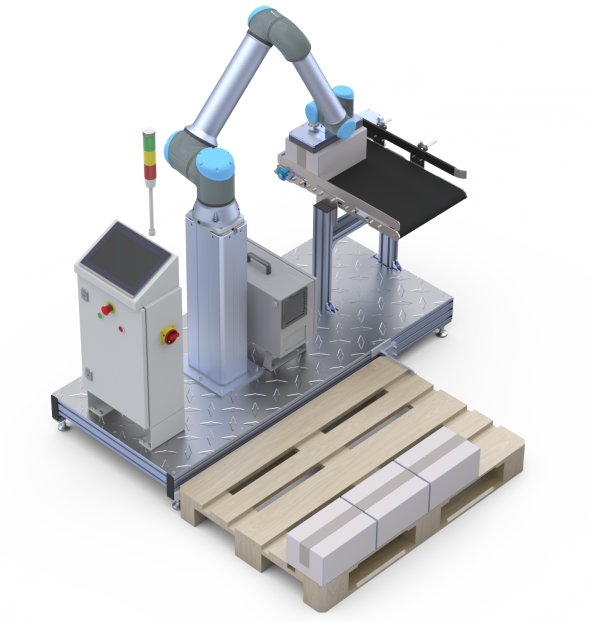

Se trata de células de paletizado que incorporan robots colaborativos para trabajo en entornos compartidos.

Su capacidad de carga y velocidad están adaptadas para poder trabajar sin necesidad de vallado y compartiendo el espacio de manera segura con los trabajadores. Son células «Plug & Play».

FRIENDLY SYSTEMS

Ingetech Robotics

<p

PANTALLA TÁCTIL AMIGABLE

![]()

NUESTRAS CÉLULAS DE PALETIZADO

PUEDEN INTEGRAR UNA PANTALLA TÁCTIL DE 12"

DE MANEJO SENCILLO E INTUITIVO.