CÉLULAS DE PALETIZADO CON ROBOT COLABORATIVO

Para paletizar en entornos compartidos con los trabajadores, y sin necesidad de vallado. Cuando el producto a paletizar no supera las 10 ud/min, y su peso unitario no supera los 20 kg.

La integración de Células de paletizado con robot colaborativo, es la opción más amigable de nuestro programa para el paletizado de su empresa.

Si su producción es media o baja, hasta 10 cajas/min en picking unitario, si dispone de poco espacio, si no quiere una instalación con vallado, o si en el entorno de su paletizado trabajan sus operarios, usted necesita un “Robot colaborativo o COBOT”. Nuestras células de paletizado incorporan los robots colaborativos con las mayores medidas de seguridad conocidas hasta ahora en robótica.

PALETIZADO POR ROBOT COLABORATIVO

CÉLULAS PLUG & PLAY

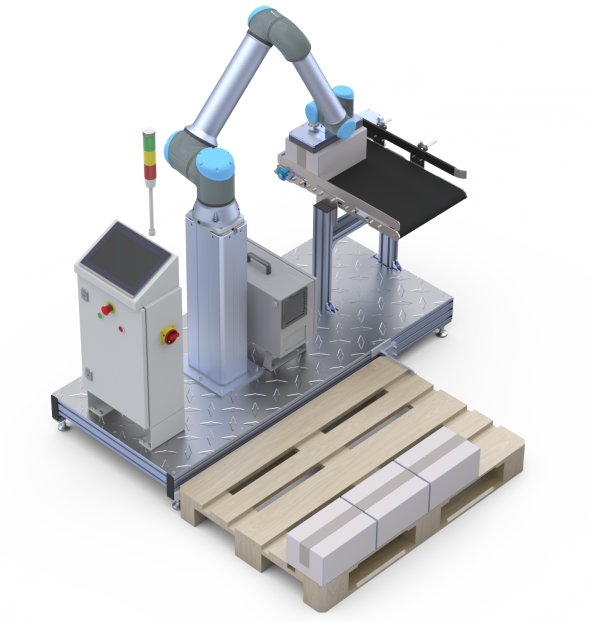

CÉLULA DE PALETIZADO COLABORATIVO

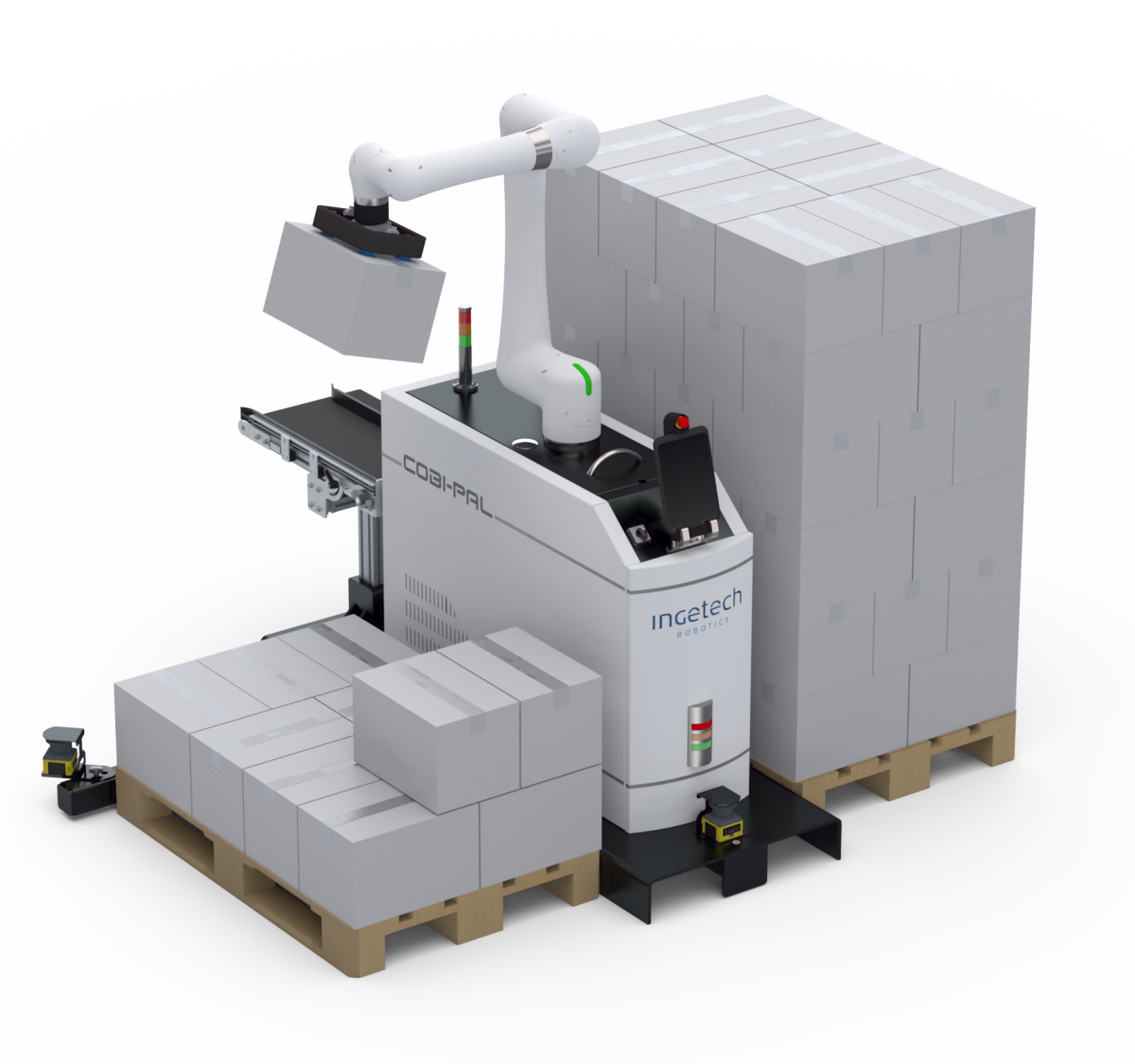

COBI-PAL

NÚMERO DE LÍNEAS

1

NÚMERO DE PALÉS

1-2

TIPO DE PRODUCTOS

Cajas

PESO MÁXIMO UD.

20 Kg

UNIDADES / MIN

< 8

EXTRACCIÓN PALÉS

Manual

CÉLULA DE PALETIZADO POR ROBOT COLABORATIVO

¡La mejor solución en CÉLULAS DE PALETIZADO COLABORATIVO!

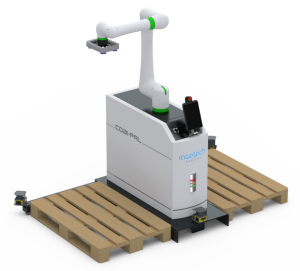

Nuestro paletizador por robot colaborativo COBI-PAL es el paletizador técnicamente más avanzado del mercado.

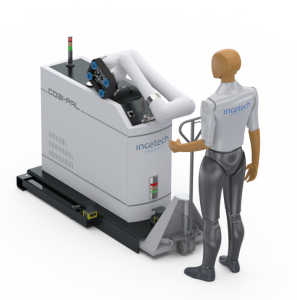

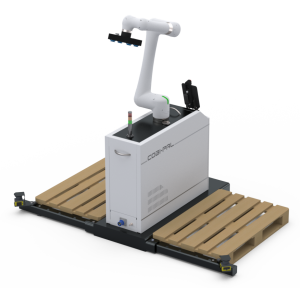

Una solución ultra-compacta con el concepto PLUG & PLAY. Se trata de un único bastidor de fácil transporte, por transpaleta, y listo para su colocación en su final de línea. Aire, tensión, y ¡A paletizar!.

Hemos pensado en que su puesta en marcha sea FÁCIL y RÁPIDA, sabemos que su tiempo es importante, y además queremos facilitarle las cosas.

| MAYOR CAPACIDAD DE CARGA | <20Kg (Según robot) |

| MAYOR ALCANCE | <1.700 mm |

| MAYOR VELOCIDAD DE TRABAJO | 10 cajas/min – 600 ud/h |

| MAYOR ALTURA DE PALETIZADO | 1.600 mm – 2.200 mm con columna |

| MAYOR VERSATILIDAD | 1 ó 2 Posiciones de paletizado |

| MAYOR SEGURIDAD | Escáner láser perimetral 360º |

| MAYOR PRECISIÓN | Posición controlada de picking |

| MÍNIMO ESPACIO EN PLANTA | <1M2 |

Es transportable por transpaleta manual o carretilla elevadora, y todos los elementos están montados sobre un bastidor ultra compacto. Usted recibe la célula con el robot recogido en posición de transporte, para que pueda moverlo sin problema y ubicarlo en la posición deseada. Su fácil portabilidad le permite además, su utilización en diferentes líneas de producción.

ROBOTS COLABORATIVOS

ROBOT FANUC CRX-10iAL

DATOS TÉCNICOS:

El CRX es la elección perfecta para un primer paso hacia la automatización. Es muy fácil de utilizar, tiene varias funcionalidades user friendly, como una Tablet Teach Pendant y programación «Drag and Drop». la última novedad de FANUC en la gama de robots colaborativos ofrece la reconocida fiabilidad de FANUC.

CARGA MÁXIMA Kg

VELOCIDAD m/s

ALCANCE mm

PRECISIÓN mm

ROBOT FANUC CRX-20iAL

DATOS TÉCNICOS:

El CRX es la elección perfecta para un primer paso hacia la automatización. Es muy fácil de utilizar, tiene varias funcionalidades user friendly, como una Tablet Teach Pendant y programación «Drag and Drop». la última novedad de FANUC en la gama de robots colaborativos ofrece la reconocida fiabilidad de FANUC.

CARGA MÁXIMA Kg

VELOCIDAD m/s

ALCANCE mm

PRECISIÓN mm

ROBOT FANUC CRX-30iA

DATOS TÉCNICOS:

El CRX es la elección perfecta para un primer paso hacia la automatización. Es muy fácil de utilizar, tiene varias funcionalidades user friendly, como una Tablet Teach Pendant y programación «Drag and Drop». la última novedad de FANUC en la gama de robots colaborativos ofrece la reconocida fiabilidad de FANUC.

CARGA MÁXIMA Kg

VELOCIDAD m/s

ALCANCE mm

PRECISIÓN mm

¿Quiere saber más sobre ROBÓTICA COLABORATIVA?

¿Tiene dudas si la opción de una célula colaborativa es la que más le conviene?

INGETECH ROBOTICS se lo explica…

La Robótica Colaborativa es una opción útil en aquellas aplicaciones en las que como su nombre indica, existe o es necesaria una colaboración real entre hombre y robot. Para estas aplicaciones la velocidad del robot así como el tipo de garra a utilizar se deben adecuar para preservar la seguridad de las personas, ya que no integran vallados ni barreras de seguridad para proteger el entorno del robot.

Así pues, su integración está indicada donde la instalación de un robot industrial tradicional no es posible.

Como todas las aplicaciones, la Robótica Colaborativa tiene ventajas y desventajas, por lo que serán nuestros Ingenieros los que le asesorarán de la conveniencia o no de su aplicación.

Pese a que se habla de ROBOTS COLABORATIVOS, debemos pensar en Aplicaciones Colaborativas, ya que son muchos los factores que determinan el que una aplicación pueda considerarse como colaborativa. En una aplicación de ROBÓTICA COLABORATIVA, hay que tener en cuenta:

¿Cómo va a trabajar el robot? Si es necesaria la interacción humana o si existe presencia cercana a él.

¿Qué tiempo de ciclo necesitamos? Ya que su velocidad es limitada en modo colaborativo, deberemos calcular su capacidad de trabajo. Y lo que es más importante, si es posible su aplicación en relación a su rendimiento.

¿Se prevé la instalación de métodos alternativos de seguridad? La célula puede incorporar scanner rotativos como elemento adicional de seguridad cuando deseamos aumentar la velocidad del robot.

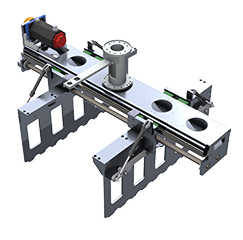

¿Qué herramienta o garra va a llevar? La garra o herramienta que instalemos deberá ser colaborativa. Un mal diseño de ésta, hará que nuestras células de paletizado no sean colaborativas.

Tenidos en cuenta estos factores, resolveremos si es necesario la instalación de sistemas de seguridad añadidos.

Es el conjunto de la instalación el que determina su certificación y marcado CE como aplicación colaborativa.

¿Necesita una solución con mayores prestaciones?

CÉLULAS DE PALETIZADO

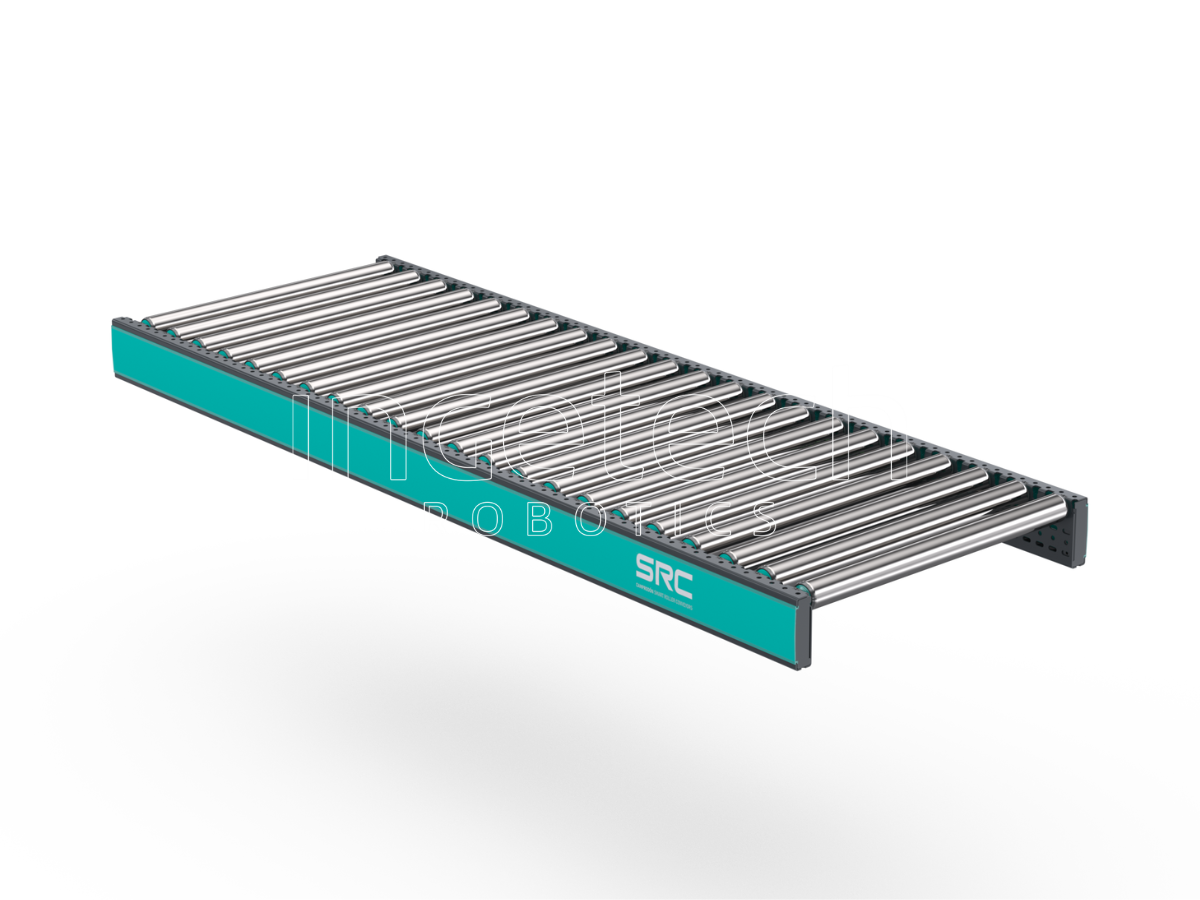

Fabricamos células de paletizado compactas con producciones de hasta 12 cajas/minuto.

Su principal característica es que su diseño ha sido optimizado para ocupar el mínimo espacio en planta, su concepto es «plug $ play», y se pueden transportar por transpaleta o carretilla elevadora.

Células de paletizado para altas producciones o cargas pesadas >20 Kg/unidad.

Se trata de células con robots de mayor tamaño y que pueden realizar pickings unitarios, de varias cajas a la vez, de filas completas, o de capas completas. Su diseño se realiza ajustado a la aplicación.

FRIENDLY SYSTEMS

Ingetech Robotics

TABLET ANDROID PARA UN USO AMIGABLE

FÁCIL DE PROGRAMAR Y DE UTILIZAR

Si sabe manejar una tablet,

sabe manejar un robot