PALETIZADO DE ALTA PRODUCCIÓN

Hablamos de altas producciones o altas prestaciones cuando el producto a paletizar supera las 15 ud/min, y/o su peso unitario supera los 20 kg.

Cuando el tiempo de ciclo necesario de robot baja de los 5 segundos, es necesario un sistema de paletizado de alta producción, o altas prestaciones. Un robot es muy rápido, pero no tanto como para alcanzar producciones tan altas. Para ello vamos a necesitar realizar el picking de varias cajas o productos a la vez. Por tanto vamos a necesitar un mayor «Payload» o capacidad de carga por parte del robot. Los robots que deberemos instalar, serán mucho mayores que los que incluimos en las pequeñas células compactas.

Para cubrir estas producciones hemos desarrollado varias células en las que el picking se realiza sobre agrupaciones de al menos de 2 o 3 unidades, agrupaciones de filas completas, o incluso capas completas de cajas.

MODELOS ESTÁNDAR PARA ALTA PRODUCCIÓN

CÉLULA DE PALETIZADO

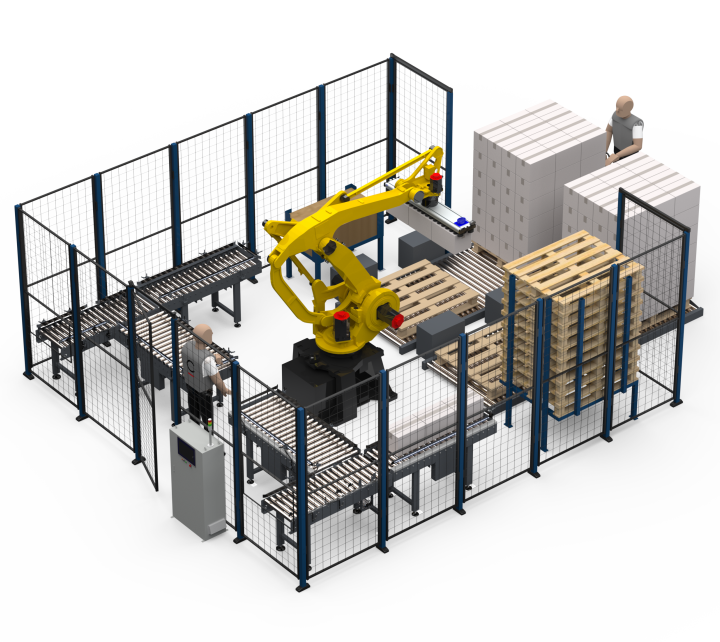

PAL.10.01

SISTEMAS DE PALETIZADO POR ROBOT

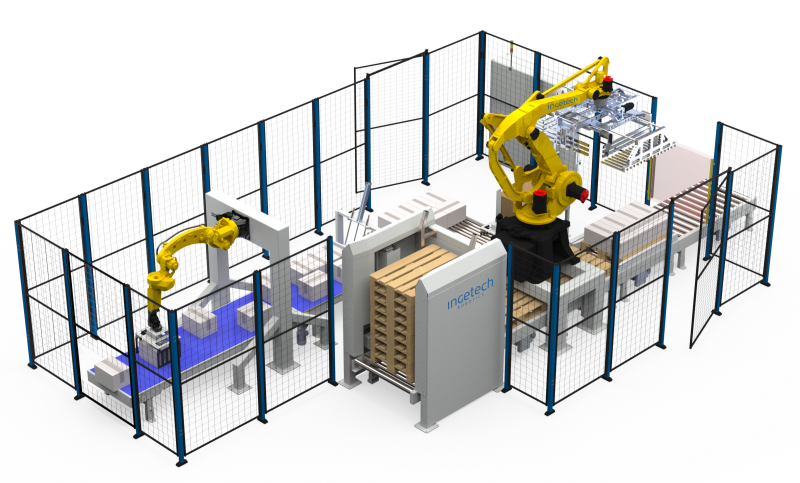

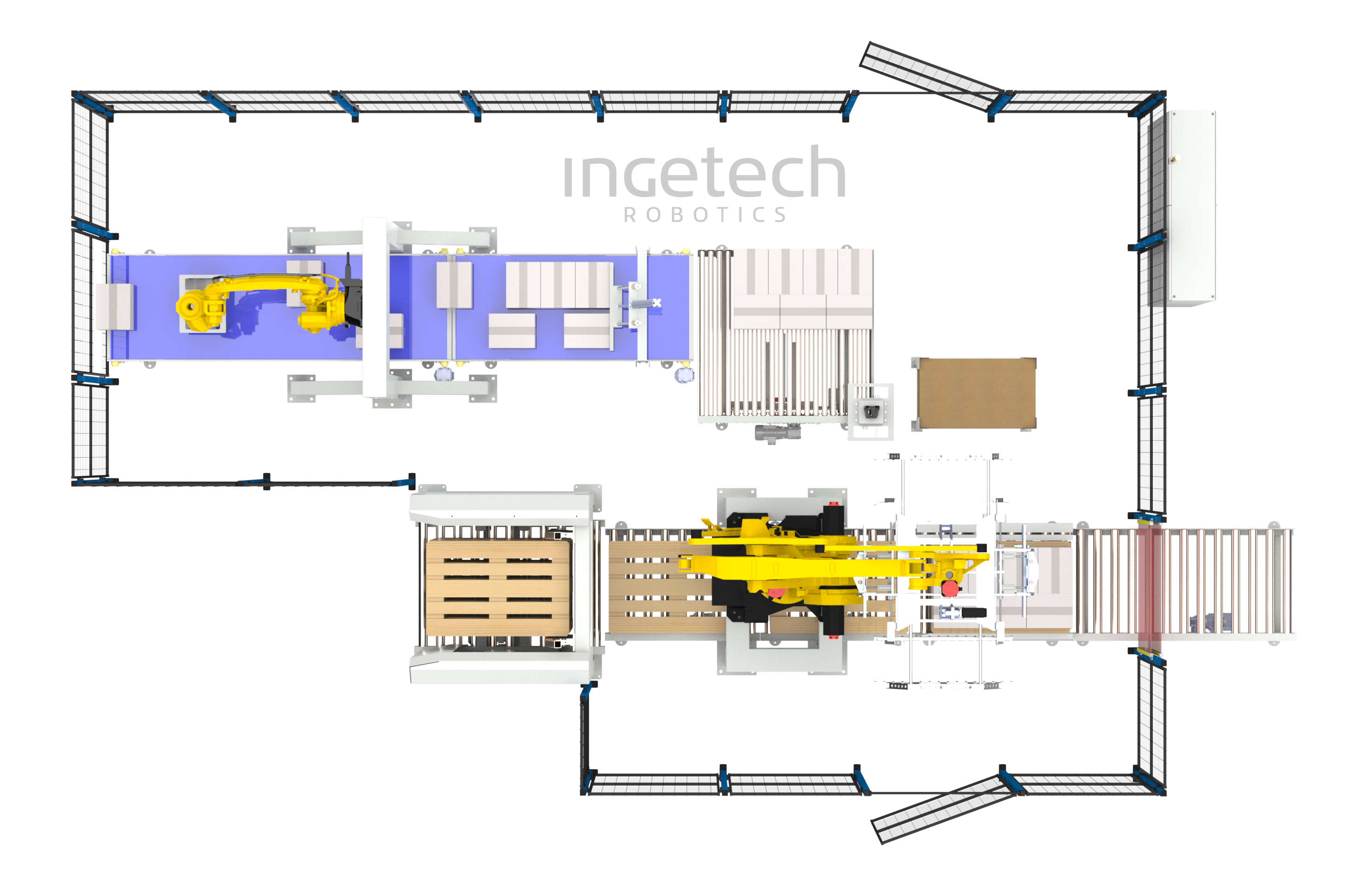

PAL10.01 PALETIZACIÓN POR FILAS.

30 Cajas/min.

Con la misma filosofía de nuestras células compactas de paletizado, hemos desarrollado una célula estándar para el paletizado de altas producciones con picking por filas.

Las células pueden incorporar una amplia variedad de modelos de robot, aunque como estándar montan un Robot FANUC de alta dinámica con capacidades de 185 y 300 kg. de carga en punta incluida la garra.

Para ello, integramos la alimentación de las cajas a la célula a través de nuestros sistemas de transporte de cajas por caminos de rodillos. La correcta orientación y posicionado de las cajas, la gestionamos a través de elementos como transfers ortogonales o giradores que nos permiten la formación de todo tipo de mosaicos.

La capacidad de producción de la Célula PAL 10 es de 30 cajas/min*

*Nota: producción calculada para caja de 300 x 400 x 200 mm. Mayor producción para cajas de menor tamaño.

SISTEMAS DE PALETIZADO POR ROBOT

PALETIZACIÓN POR FILAS

Con la misma filosofía de nuestras células compactas de paletizado, hemos desarrollado una célula estándar para el paletizado de altas producciones con picking por filas.

Las células pueden incorporar una amplia variedad de modelos de robot, aunque como estándar montan un Robot FANUC de alta dinámica con capacidades (según peso de las cajas) de 185 y 300 kg. de carga en punta incluida la garra.

Para ello, integramos la alimentación de las cajas a la célula a través de nuestros sistemas de transporte de cajas por caminos de rodillos. La correcta orientación y posicionado de las cajas, la gestionamos a través de elementos como transfers ortogonales o giradores que nos permiten la formación de todo tipo de mosaicos.

Las ventajas principales de la célula son:

CÉLULA DE PALETIZADO

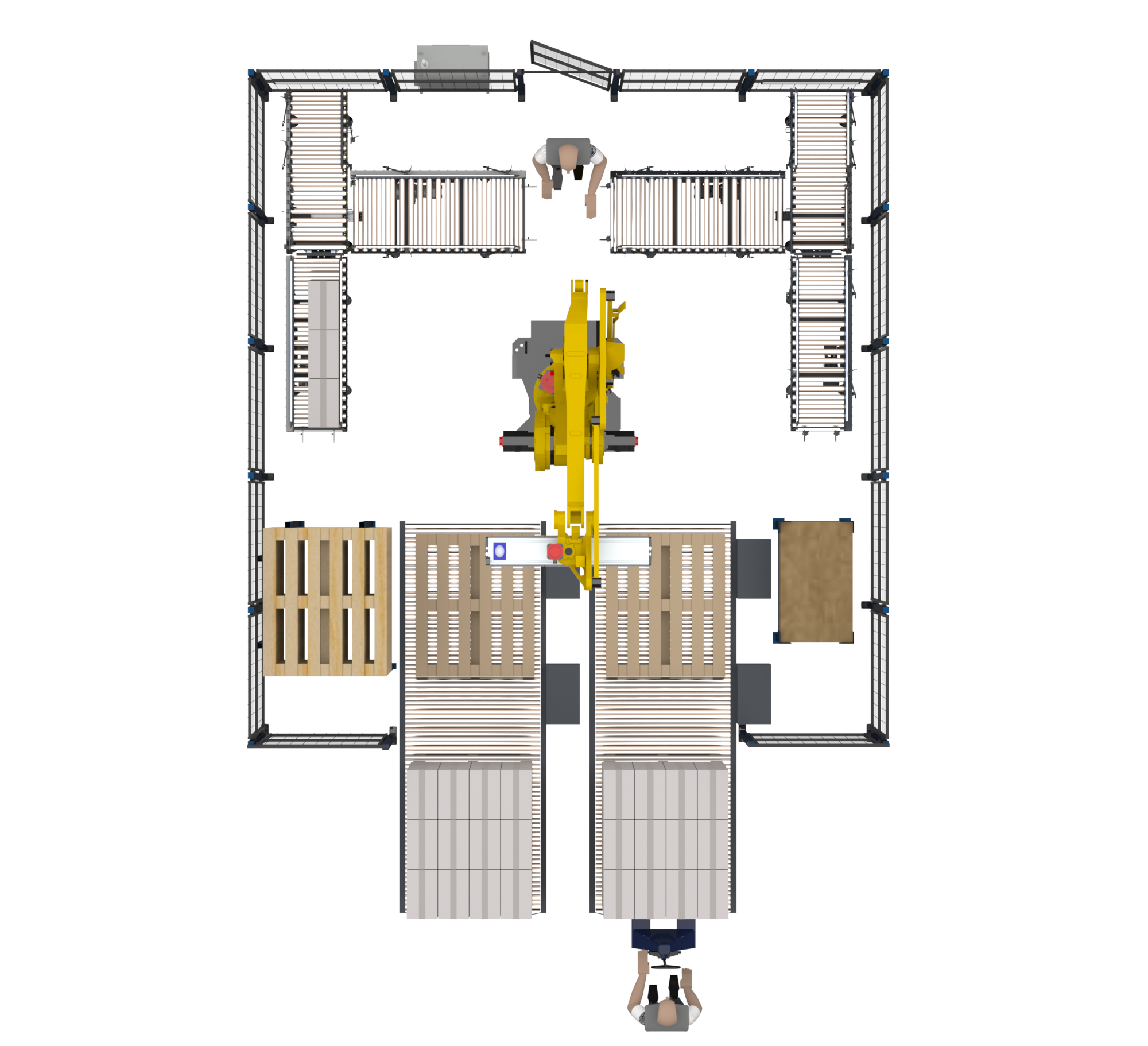

PAL.20.01

SISTEMAS DE PALETIZADO POR ROBOT

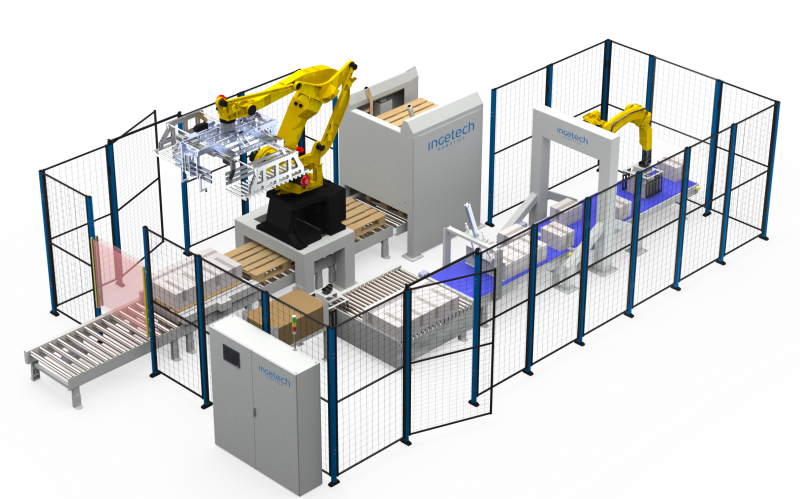

PAL20.01 PALETIZACIÓN

POR CAPAS COMPLETAS

40 Cajas/min

Cuando por nuestra producción necesitamos aumentar la velocidad de paletizado, nuestras células con picking de capa completa son la mejor solución.

Con la incorporación de robots de altas prestaciones, aumentamos la capacidad de carga hasta 300 kg de payload. La capacidad de paletizado que nuestras CÉLULAS DE CAPA COMPLETA pueden alcanzar, llega hasta 30 cajas/minuto.

Para la configuración de la capa completa, integramos un transportador de giro y justificación de cajas, y una mesa de rodillos de formado de capa completa..Estos sistemas de transporte, permiten la formación de todo tipo de mosaicos.

Nuestra amplia variedad de garras, nos permiten su aplicación a numerosos sectores y tipos de producto a paletizar, con sistemas de cogida por vacío, por palas o mediante garras de dedos.

La capacidad de producción de la Célula PAL 20 es de 40 cajas/min*

*Nota: producción calculada para caja de 300 x 400 x 200 mm. Mayor producción para cajas de menor tamaño.

CÉLULA DE PALETIZADO

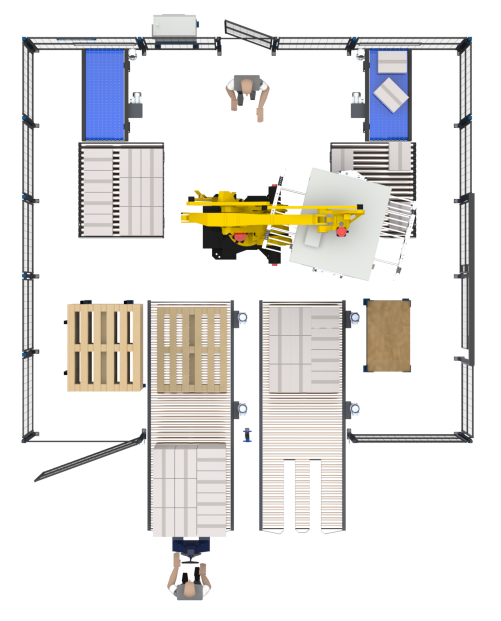

PAL.20.03

SISTEMAS DE PALETIZADO POR ROBOT

PAL20.03 PALETIZACIÓN

POR CAPAS COMPLETAS

3 LÍNEAS DE PRODUCCIÓN

40 Cajas/min

Si necesitamos paletizar de mas de 2 líneas de producción y queremos unificar las mismas en una única célula de paletizado, necesitamos nuestras célula de picking de capa completa PAL20.03

Esta célula de altas prestaciones, incorpora un robot de alta capacidad con un payload de 300 kg con capacidad de absorber hasta 12-14 cajas/min x línea.

Para la configuración de la capa completa, integramos 1 módulo Sorter + 1 Camino de rodillos almenado.

Este conjunto nos permite el giro de cajas, su justificado y el formado secuencial de los mosaicos.

Una vez formado el mosaico deseado, realizamos el picking de la capa completa de cajas. Este sistema permite una gestión de las cajas y su posición de paletizado a una velocidad muy alta.

La capacidad de producción de la Célula PAL 20.03 es de 40 cajas/min*

*Nota: producción calculada para caja de 300 x 400 x 200 mm. Mayor producción para cajas de menor tamaño.

CÉLULA DE PALETIZADO

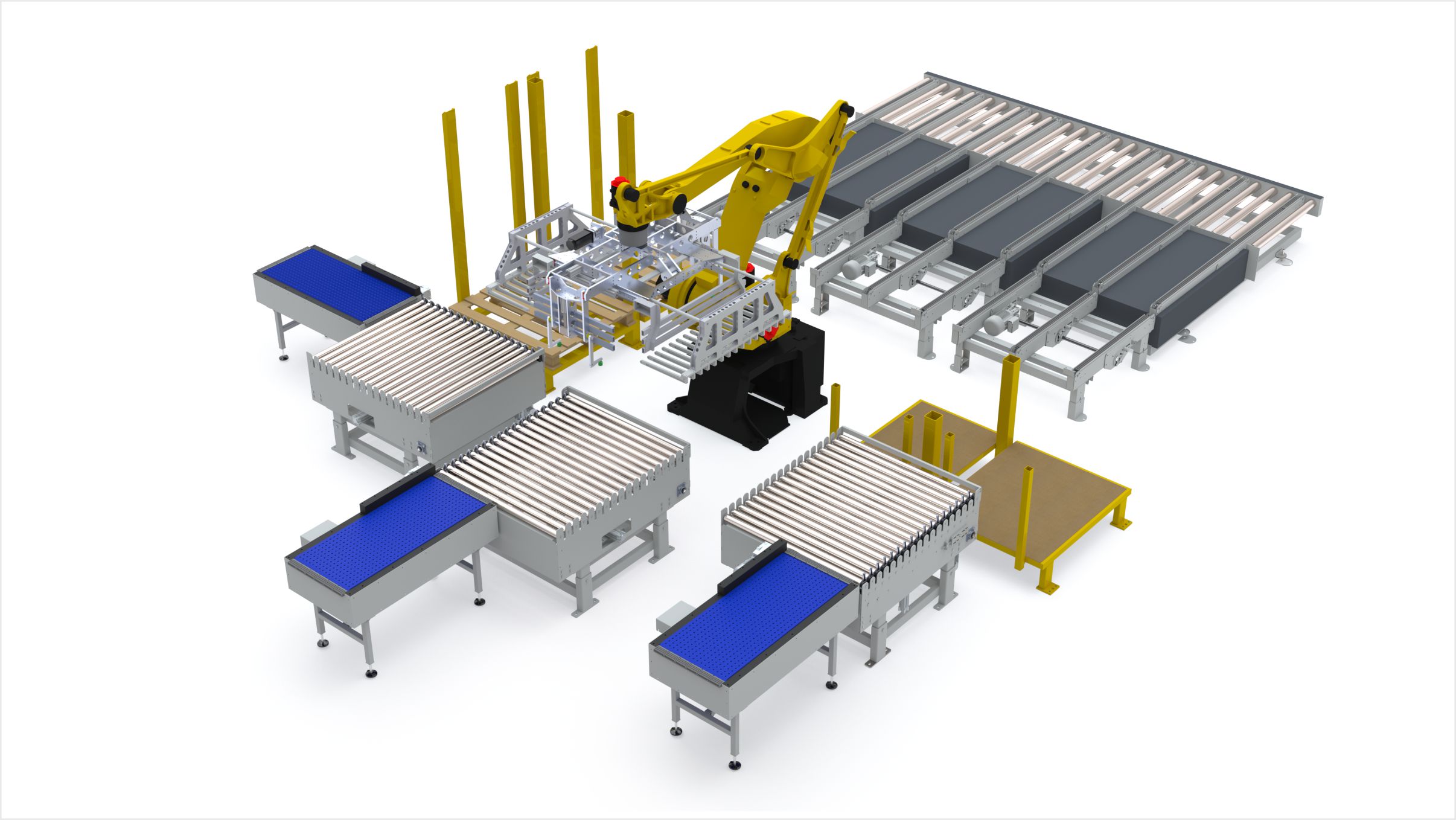

PAL.100

SISTEMAS DE PALETIZADO POR ROBOT

PAL100 PALETIZACIÓN

POR CAPAS COMPLETAS

60 Cajas/min

Cuando por nuestra producción necesitamos aumentar la velocidad de paletizado, nuestras células con picking de capa completa son la mejor solución.

Con la incorporación de robots de altas prestaciones, aumentamos la capacidad de carga hasta 300 kg de payload. La capacidad de paletizado que nuestras CÉLULAS DE CAPA COMPLETA PAL100 pueden alcanzar, llega hasta 1 caja x segundo.

Para la configuración de la capa completa, integramos en la célula un pórtico donde montamos un robot de 6 ejes para realizar el preformado de los mosaicos sobre un transportador de banda modular con un tope neumático. Posteriormente y sobre un transportador de rodillos almenado, realizamos la justificación de la capa completa de cajas. Este sistema permite una gestión de las cajas y su posición de paletizado a una velocidad muy alta.

Cuando por nuestra producción necesitamos aumentar la velocidad de paletizado, nuestras células con picking de capa completa son la mejor solución.

La capacidad de producción de la Célula PAL 10 es de 60 cajas/min*.

*Nota: producción calculada para caja de 300 x 400 x 200 mm. Mayor producción para cajas de menor tamaño.

EJEMPLOS DE PRODUCTOS PALETIZABLES

PALETIZADO DE CAJAS DE CARTÓN

Picking unitario, por filas, o por capa completa

Podemos paletizar distintos tipos de cajas de cartón. Tipo folding, Cajas de aletas de cartón ondulado, cartón piedra, etc. Con cerrado por cinta o encoladas.

Diseñamos y fabricamos la garra del robot conforme a la forma, peso y material de las mismas.

· Pesos hasta 32 kg/ud. para paletizado unitario

· Desde tamaño 200 x 200 hasta 400 x 600 mm

· Paletizado mediante picking por filas para medias producciones.

· Paletizado mediante picking de capa completa para grandes producciones o cargas puntuales elevadas.

· Etc

PALETIZADO DE SACOS

Células PAL1 y PAL2 – Hasta 25 Kg/Ud

Célula PAL3 MODUPAL – Hasta 50 Kg/Ud

Con nuestras células de paletizado PAL1 y PAL2 puede realizar el paletizado de sus sacos de hasta 23 Kg. Si el peso de sus sacos es mayor, la célula de paletizado PAL3 es su solución.

Paletizamos sacos para diferentes tipos de producto, tanto con picking por vacío como por garras de uñas y/o pinza:

· Paletizado de sacos de pienso

· Paletizado de sacos de azúcar

· Paletizado de sacos de harina

· Paletizado de sacos de café

· Paletizado de sacos de grano

· Paletizado de sacos industria química

· Paletizado de sacos de cemento

· Paletizado de sacos de granza

· Paletizado de sacos de arena

· Etc

PALETIZADO DE CAJAS DE FRUTA

Picking unitario, por filas, o por capa completa

Realizamos proyectos «llaves mano» para el paletizado y despaletizado en la industria hortofrutícola. Nos ajustamos a la producción de cada cliente adaptando nuestros sistemas de PICKING y el diseño de las garras para optimizar la solución.

Paletizamos cajas plásticas de diferentes formatos con posibilidad de:

· Despaletizado de caja llena para alimentación de líneas de proceso.

· Paletizado mediante picking unitario para producciones pequeñas.

· Paletizado mediante picking por filas para medias producciones.

· Paletizado mediante picking de capa completa para grandes producciones o cargas puntuales elevadas.

· Etc

PALETIZADO DE SACOS

Células PAL1 y PAL2 – Hasta 25 Kg/Ud

Célula PAL3 MODUPAL – Hasta 50 Kg/Ud

Con nuestras células de paletizado PAL1 y PAL2 puede realizar el paletizado de sus sacos de hasta 23 Kg. Si el peso de sus sacos es mayor, la célula de paletizado PAL3 es su solución.

Paletizamos sacos para diferentes tipos de producto, tanto con picking por vacío como por garras de uñas y/o pinza:

· Paletizado de sacos de pienso

· Paletizado de sacos de azúcar

· Paletizado de sacos de harina

· Paletizado de sacos de café

· Paletizado de sacos de grano

· Paletizado de sacos industria química

· Paletizado de sacos de cemento

· Paletizado de sacos de granza

· Paletizado de sacos de arena

· Etc

PALETIZADO DE BOTES, LATAS Y CUBOS

Hasta 25 l/ud

Con las células de paletizado PAL1 y PAL2 puede realizar el paletizado de sus botes o latas de hasta 25 l mediante picking unitario.

Producciones de hasta 35 palés (+ de 4.000 uds.) por turno.*

Integramos la programación necesaria para el paletizado de botes estándar con cierre tipo PAIL o tipo BALLESTA para diferentes sectores:

CIERRES TIPO PAIL Y BALLESTA ESTÁNDAR

· Paletizado de latas o botes de diámetro 180 mm superior

· Paletizado de latas o botes de diámetro 240 mm superior

· Paletizado de latas o botes de diámetro 292 mm superior

· Paletizado de latas o botes de diámetro 305 mm superior

*Cálculo para paletizado de botes de diámetro 240 mm y h=300 mm (Aprox. 12 litros)

PALETIZADO DE BOTES, LATAS Y CUBOS

Hasta 25 l/ud

Con las células de paletizado PAL1 y PAL2 puede realizar el paletizado de sus botes o latas de hasta 25 l mediante picking unitario.

Producciones de hasta 35 palés (+ de 4.000 uds.) por turno.*

Integramos la programación necesaria para el paletizado de botes estándar con cierre tipo PAIL o tipo BALLESTA para diferentes sectores:

CIERRES TIPO PAIL Y BALLESTA ESTÁNDAR

· Paletizado de latas o botes de diámetro 180 mm superior

· Paletizado de latas o botes de diámetro 240 mm superior

· Paletizado de latas o botes de diámetro 292 mm superior

· Paletizado de latas o botes de diámetro 305 mm superior

*Cálculo para paletizado de botes de diámetro 240 mm y h=300 mm (Aprox. 12 litros)

PALETIZADO DE SACOS

Células PAL1 y PAL2 – Hasta 25 Kg/Ud

Célula PAL3 MODUPAL – Hasta 50 Kg/Ud

Con nuestras células de paletizado PAL1 y PAL2 puede realizar el paletizado de sus sacos de hasta 23 Kg. Si el peso de sus sacos es mayor, la célula de paletizado PAL3 es su solución.

Paletizamos sacos para diferentes tipos de producto, tanto con picking por vacío como por garras de uñas y/o pinza:

· Paletizado de sacos de pienso

· Paletizado de sacos de azúcar

· Paletizado de sacos de harina

· Paletizado de sacos de café

· Paletizado de sacos de grano

· Paletizado de sacos industria química

· Paletizado de sacos de cemento

· Paletizado de sacos de granza

· Paletizado de sacos de arena

· Etc

PALETIZADO DE SACOS

Células PAL1 y PAL2 – Hasta 25 Kg/Ud

Célula PAL3 MODUPAL – Hasta 50 Kg/Ud

Con nuestras células de paletizado PAL1 y PAL2 puede realizar el paletizado de sus sacos de hasta 23 Kg. Si el peso de sus sacos es mayor, la célula de paletizado PAL3 es su solución.

Paletizamos sacos para diferentes tipos de producto, tanto con picking por vacío como por garras de uñas y/o pinza:

· Paletizado de sacos de pienso

· Paletizado de sacos de azúcar

· Paletizado de sacos de harina

· Paletizado de sacos de café

· Paletizado de sacos de grano

· Paletizado de sacos industria química

· Paletizado de sacos de cemento

· Paletizado de sacos de granza

· Paletizado de sacos de arena

· Etc

¿Necesita algo más compacto? ¿Una solucion colaborativa?

CÉLULAS DE PALETIZADO

Fabricamos células de paletizado compactas con producciones de hasta 12 cajas/minuto.

Su principal característica es que su diseño ha sido optimizado para ocupar el mínimo espacio en planta, su concepto es «plug $ play», y se pueden transportar por transpaleta o carretilla elevadora.

Se trata de células de paletizado que incorporan robots colaborativos para trabajo en entornos compartidos.

Su capacidad de carga y velocidad están adaptadas para poder trabajar sin necesidad de vallado y compartiendo el espacio de manera segura con los trabajadores. Son células «Plug & Play».

FRIENDLY SYSTEMS

Ingetech Robotics

<p

PANTALLA TÁCTIL AMIGABLE

![]()

NUESTRAS CÉLULAS DE PALETIZADO

PUEDEN INTEGRAR UNA PANTALLA TÁCTIL DE 12″

DE MANEJO SENCILLO E INTUITIVO.