CROSS BELT SORTER

DATOS BÁSICOS

TIPO DE PRODUCTOS

Cajas de cartón, bolsas, packs, etc.

DIMENSIONES Máx. de PAQUETE

600 x 1.100 mm

PESO Máx. DEL PRODUCTO

Kg

PRODUCCIÓN

Nº Máx. Ud/hora

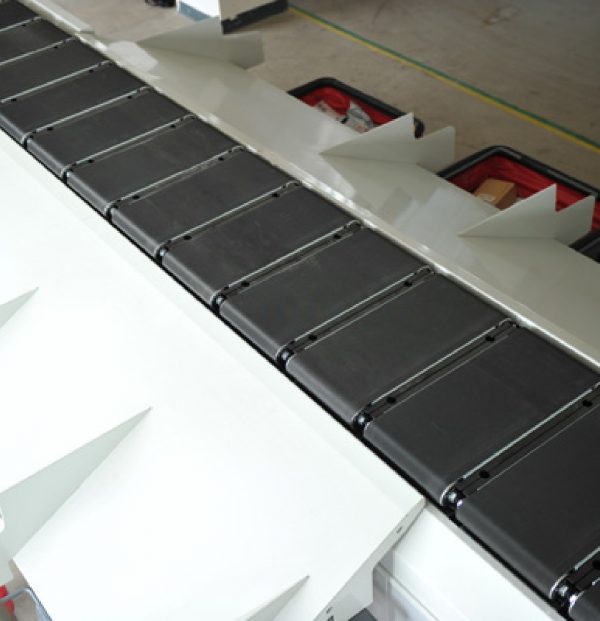

CROSS BELT SORTER

IR-CBS01

El sistema de clasificación de paquetería IR-CBS.01 es una solución de clasificación de paquetería de alta capacidad.

El dispositivo de extracción es a través de bandas transportadoras sobre un sistema giro en Loop.

Capaz de funcionar a velocidades de hasta 2,0 metros por minuto, el clasificador de cinta transversal vertical puede alcanzar tasas de clasificación de hasta 16.000 piezas por hora. Está diseñado para clasificación bidireccional y de alta velocidad en ambos lados al mismo tiempo.

Su construcción es modular para un fácil mantenimiento. Ocupa poco espacio en su versión VERTICAL, que se configura en línea recta con los carros dispuestos en bucle cerrado vertical.

Los componentes clave del sistema de clasificación de cinta transversal vertical incluyen

- El sistema de alimentación. Semiautomática o manual. Alimentación desde la parte superior o lateral del clasificador de cinta cruzada.

- El host del clasificador, El sistema clasificador de banda incorpora tecnología de accionamiento servo directo que proporciona un arranque instantáneo en milisegundos para garantizar que los artículos se ubiquen en el centro del transportador durante la carga, así como reducir las tasas de error de clasificación durante la descarga.

- El escáner de código de barras. El escáner de código de barras lo escanea automáticamente para obtener el destino de clasificación del artículo. en las tolvas o rampas de salida. El sistema puede disponer de sistema de control completo DWS (Volumétrico, pesaje y escaneo).

- Sistema de salida Hay diferentes tipos de salidas para adaptarse a la diversa gama de elementos que se pueden manipular. Los artículos se pueden clasificar directamente en salidas como rampas, caminos de rodillos, jaulas o contenedores, etc.

- Sistema de control: Al utilizar la comunicación inalámbrica distribuida de ondas con fugas y la tecnología de itinerancia rápida, puede lograr una comunicación instantánea y un control preciso de todos los carros sin importar la longitud del bucle. El sistema de control utiliza métodos de comunicación inteligentes como Profinet, TCP / IP y RS485. Para completar la comunicación entre la computadora y el sistema de clasificación, la tecnología Prodave y la tecnología OPC se utilizan para proporcionar diagnóstico y mantenimiento de fallas inteligentes a distancia.

CROSS BELT SORTER

DATOS TÉCNICOS

| CAPACIDAD DEL SISTEMA: | 10.000-16.000 Ud/hora |

| DIMENSIONES PAQUETE: | Según modelo (Mínimo A=1000 L =100 h=1 mm) |

| PESO PAQUETE : | 0,05-30 Kg |

| VELOCIDAD DE TRANSPORTE: | 90 m/min |

| ANCHO DE TRANSPORTE: | 280 – 440 -540 mm |

| NÚMERO DE DIVERTERS: | Variable (Longitud máx. 80 m) |

| TIPO DE TRANSPORTADORES: | Banda |

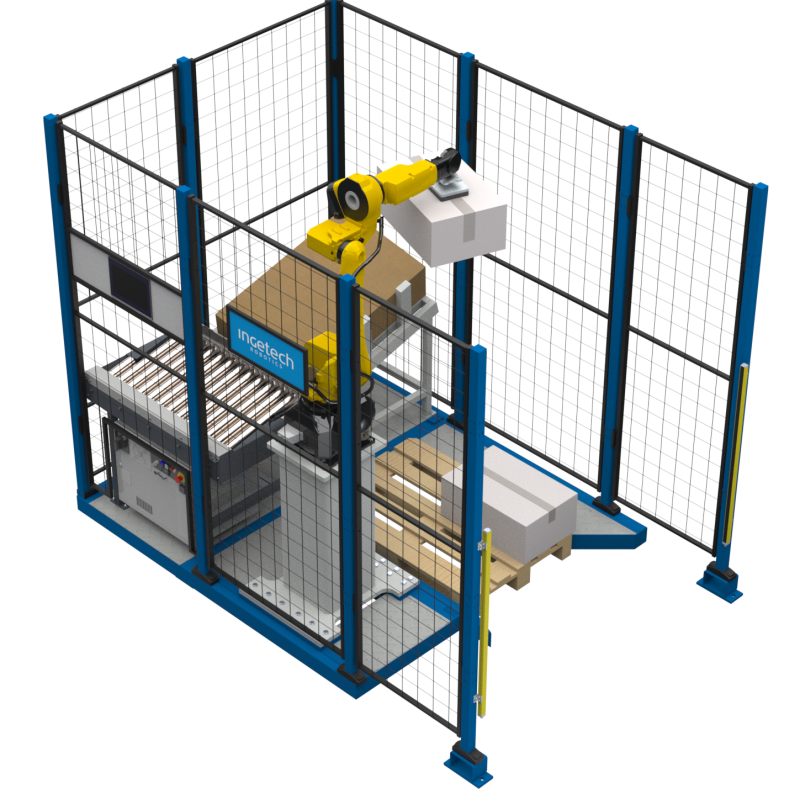

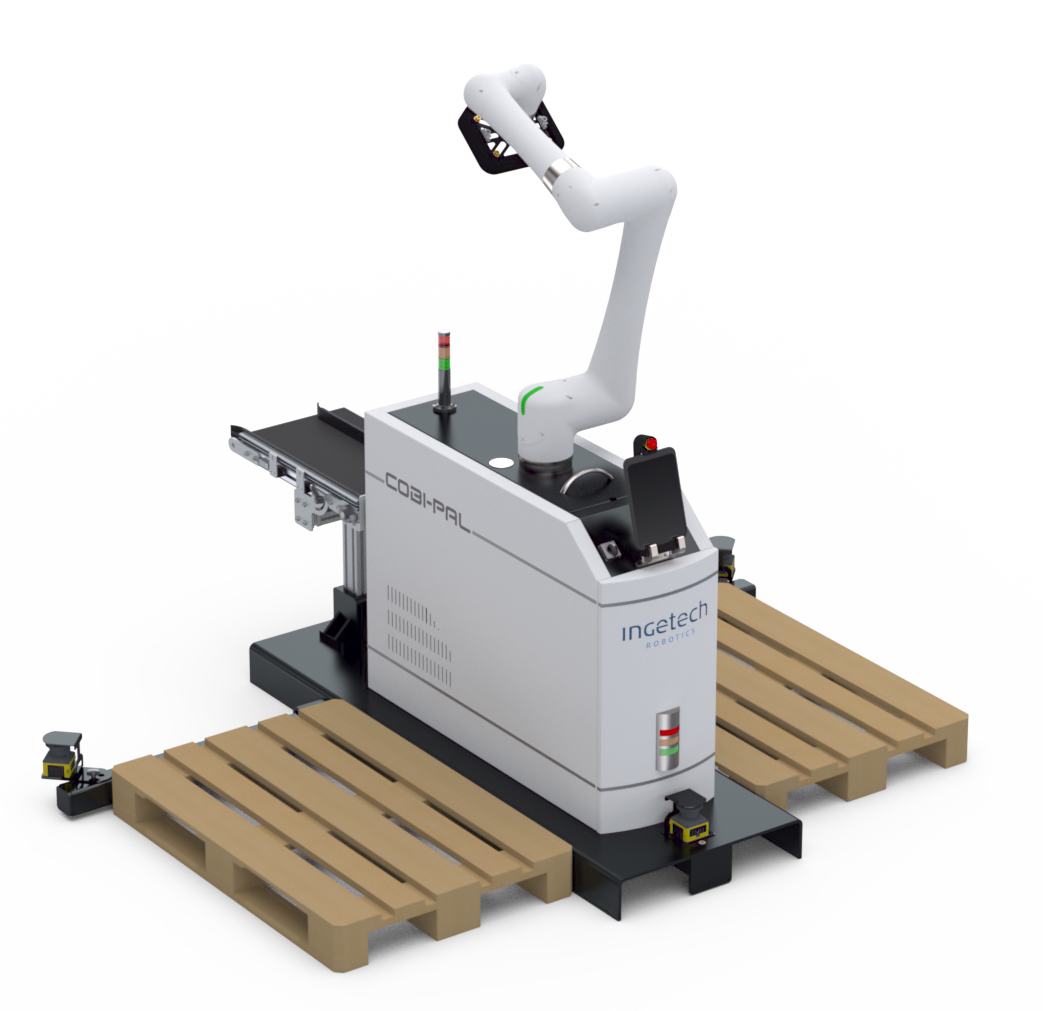

CÉLULAS COMPACTAS DE PALETIZADO

TIPOS DE ROBOTS

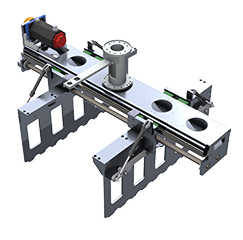

ENCAJADO