Integramos envolvedoras de alta velocidad junto a nuestras células de paletizado. Nuestras envolvedoras no necesitan de la intervención de los operarios ya que son totalmente automáticas.

Utilizan el sistema de enfardado por anillo, lo que significa más productividad, y mayor eficiencia, y por supuesto su durabilidad. Son máquinas que permiten altas producciones, pero que también pueden instalarse en producciones reducidas, donde su tipo de construcción, mucho más robusta que las envolvedoras de brazo, aumenta de manera significativa los ciclos de trabajo.

MÁQUINAS ENFARDADORAS DE ANILLO

Maquinaria periférica

ENVOLVEDORAS AUTOMÁTICAS

PRODUCCIONES BAJAS: hasta 45 palés/hora (otros modelos hasta 150 palés/hora)

- Máxima calidad, alto rendimiento y mínimo mantenimiento.

- Sistema más equilibrado que el plato giratorio: menor desgaste y mantenimiento.

- Enfardado con carga estática: las bobinas de film giran alrededor de la carga.

- Ahorro garantizado de film: pre-estiro del film del 300%. 1 m de film se convierte en 4 m

- Acabado sin colas de film gracias al eficaz sistema de corte y soldadura.

- Control auto-ajustable de la tensión en función del perfil de la carga.

- Posibilidad de aplicar enfardados anti polvo y anti lluvia eficientes.

- Posibilidad de enfardar a nivel del suelo.

- Posibilidad de aplicar fajas a cualquier altura de la carga.

¡Pregúntenos por el modelo más adecuado a su necesidad!

Maquinaria periférica

ETIQUETADO DE CAJAS

IMPRESIÓN Y ETIQUETADO DE CAJAS

Integramos etiquetadoras de cajas como la serie 2200, con impresión y aplicación de etiquetas. La serie 2200 posibilita la impresión de etiquetas y su colocación en cajas de manera simple o en varios lados, en la esquina o en la parte delantera de un paquete.

La serie 2200 tienen un rendimiento excelente y permiten reducir el tiempo de inactividad considerablemente con una alta velocidad de aplicación de más de 150 paquetes por minuto.

Ofrecen una trazabilidad completa, incluso con códigos conformes con los grados A y B de la norma ANSI, y podrá escoger entre distintos métodos de aplicación de etiquetas según sus necesidades.

La interfaz de usuario basada en el programa de gestión CoLOS de Markem-Imaje permite seleccionar las etiquetas desde una fuente de datos local o remota y visualizar los datos reales de producción en una gran pantalla táctil.

La Serie 2200 consta con miles de unidades instaladas en entornos muy exigentes que trabajan las 24 horas los 7 días de la semana, proporcionando fiabilidad, eficiencia y facilidad de uso.

La Serie 2200 dispone de una alta tecnología y ha sido diseñada para ser altamente sostenible; además, ofrece una amplia gama de aplicadores intercambiables y permite optimizar la intervención

¡Pregúntenos por el modelo más adecuado a su necesidad!

Maquinaria periférica

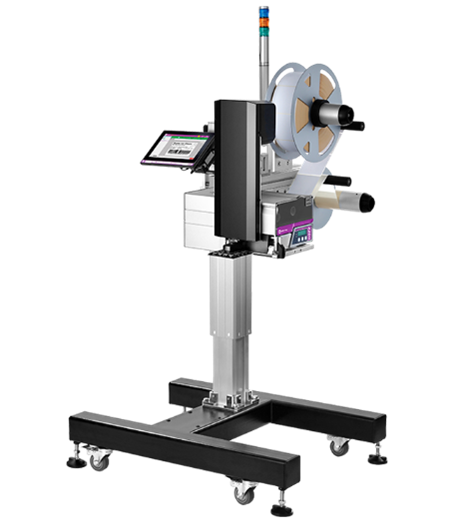

ETIQUETADO DE PALÉS

IMPRESIÓN Y ETIQUETADO DE PALÉS

Los sistemas de impresión y aplicación de la serie 2200 se utilizan para identificar palés en entornos cada vez más automatizados.

El sistema de la serie 2200 para palés puede integrarse fácilmente en cualquier línea de producción, lo que proporciona una calidad de impresión excepcional y una aplicación de etiquetas precisa para ofrecer un etiquetado que se adapta a toda la cadena de suministro.

Mejora el control de inventarios, los flujos de logística y la identificación segura de palés en el desafortunado caso de retirada de productos.

La etiquetadora para palés 2200 ofrece una trazabilidad perfecta con la validación opcional de códigos de barras en línea y una impresión de alto rendimiento en la aplicación de etiquetas simples o dobles.

Diseñada para maximizar su tiempo de actividad con una interfaz sencilla y fácil de usar y varias funciones clave que reducen las interrupciones de la línea y, al mismo tiempo, garantiza la seguridad del operario con una función de parada automática. Con el paquete de software CoLOS de Markem-Imaje dedicado a la gestión de palés, cada palé cuenta con un código único que permite su seguimiento desde el momento en que sale de la línea de producción hasta su llegada al destino final.

¡Pregúntenos por el modelo más adecuado a su necesidad!

Maquinaria periférica

CONTROL DE PESO Y DETECCIÓN DE METALES

Controladora de peso estándar y sistema de inspección para el aseguramiento de la calidad de alto nivel

Las controladoras de peso de la serie Bizerba CWEmaxx se utilizan en la industria alimentaria, principalmente para rendimientos medios y altos. En el ámbito Non-Food se emplean en líneas con un alto rendimiento y en casos donde se comprueban unos pesos nominales de hasta 15 kg.

El detector de metales VARICON integrado convierte la controladora de peso dinámica CWEmaxx en un sistema de inspección completo conforme a los requisitos de HACCP, IFS, BRC y más allá.

Los equipos combinados y verificables optimizan el aseguramiento de la calidad. Controlan el flujo de paquetes, categorizando y clasificando los productos en base a unas clases de peso libremente definidas o especificadas por la ley. Los paquetes con un peso incorrecto o contaminados con cuerpos extraños se desvían automáticamente.

Ámbito de aplicación

- Con su grado de protección elevado IP 65 y su construcción abierta y robusta en acero inoxidable, la controladora de peso combinada CWEmaxx es idónea para el uso en el ámbito de los productos frescos y en la producción.

- Para el uso en el ámbito seco o Non-Food se dispone de una variante con el grado de protección IP 54.

- El modelo CWEmaxx es particularmente interesante para los fabricantes de:

- Productos congelados

- Platos preparados

- Carne y embutidos

- Productos lácteos

- Productos Non-Food

Características principales

- Rendimiento: hasta 400 productos/min.

- Campos de pesaje: 10 – 15000 g

- Velocidad máx.: 170 m/min

- Pantalla táctil a color de 12″

- Grado de protección: IP 65

- Sistema de cambio rápido de cuerpo de cinta y cinta

- Visualización y evaluación en línea de datos con _statistics.BRAIN (opcional)

¡Pregúntenos por el modelo más adecuado a su necesidad!

VER OTRA MAQUINARIA DE PACKAGING

FORMADORAS DE CAJAS

RETRACTILADORAS

ENVOLVEDORAS

MÁQUINAS DE ENCAJADO

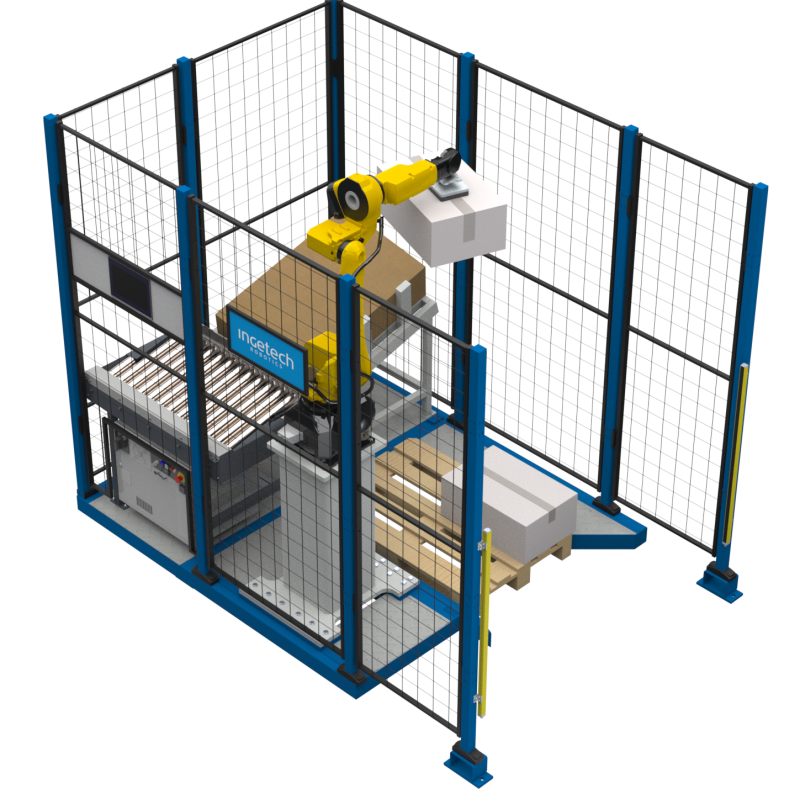

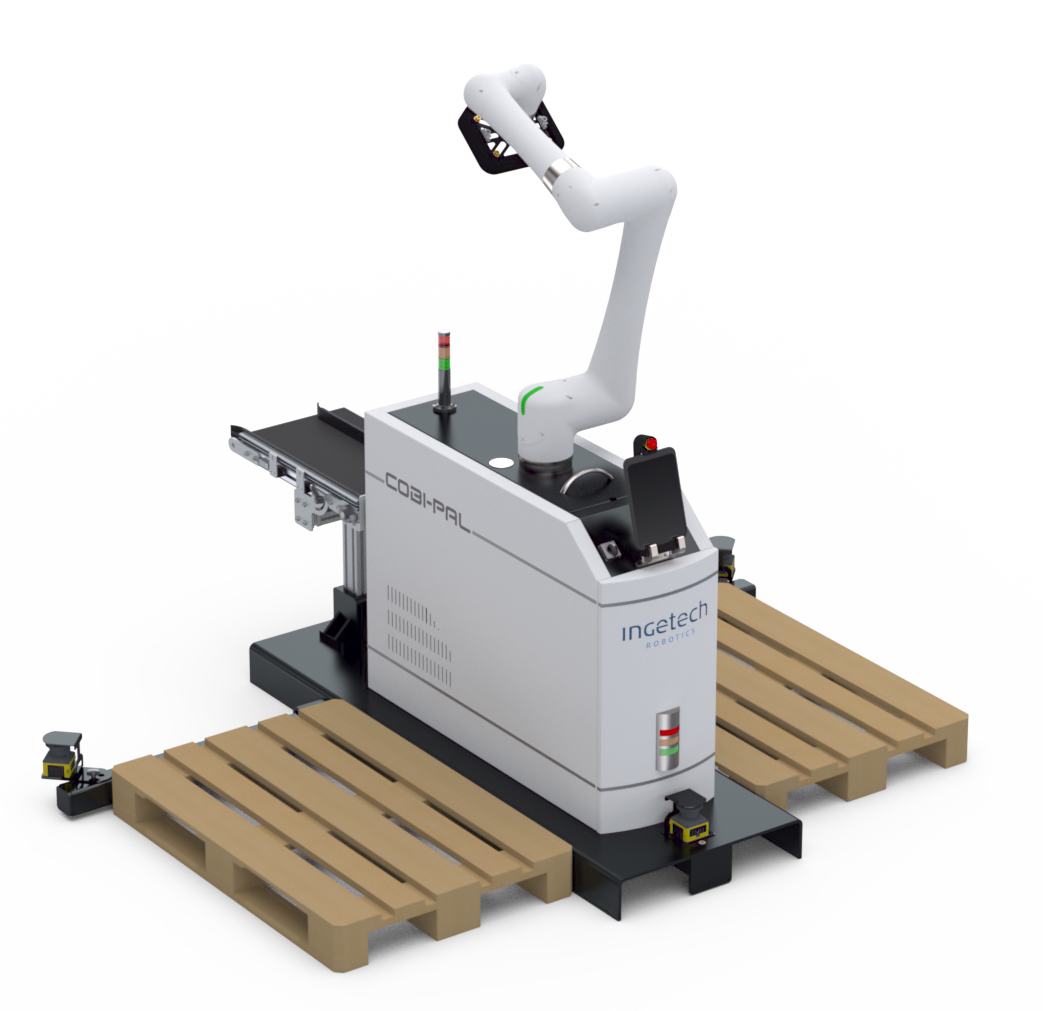

CÉLULAS COMPACTAS DE PALETIZADO

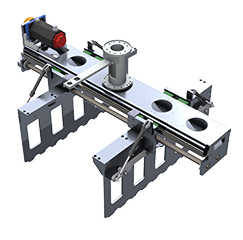

TIPOS DE ROBOTS

ENCAJADO