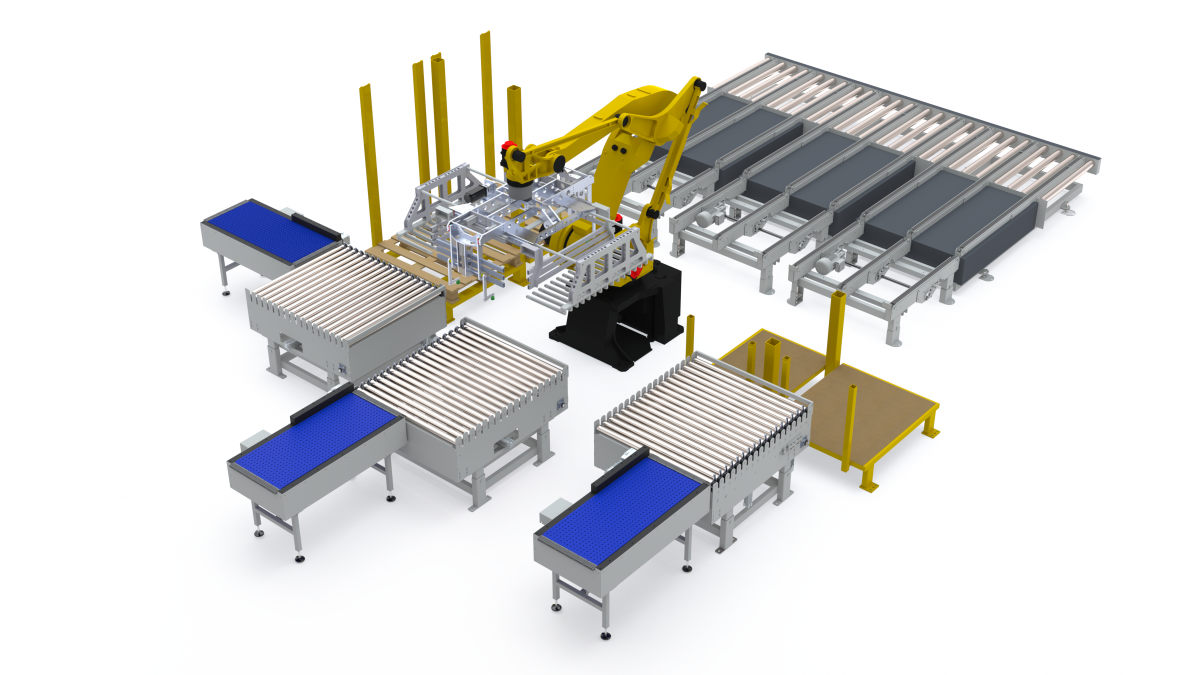

INGETECH ROBOTICS instala una nueva Célula de paletizado para 3 líneas de producción.

La célula incorpora:

- Robot FANUC M410iC/315 con payload de 315 Kg

- Garra polivalente

- Pedestal fijo de acero reforzado

- Transportadores de formado de capa

- Sistema de Transporte de palés

- Enfardadadora para 45 palés/hora

Se trata de una Célula de paletizado de capa completa que para su conformado utiliza la técnica SORTER, incorporando para cada una de sus líneas un transportador de banda modular que en un único elemento realiza las tareas de transporte, giro y justificado de cajas.

La solución se complementa con una mesa formadora de capas con sistema de escuadrado de capa completa y sistema almenado para facilitar el picking.

Esto permite el paletizado de diferentes tipos de mosaicos. En la aplicación hemos programado 18 mosaicos diferentes.

La garra la hemos diseñado a medida de la aplicación para poder realizar los siguientes procesos:

- Alimentación de palés vacíos a paletizar

- Colocación de cartón base

- Picking de capa completa con garras inferiores y palas prensoras

- Colocación de cartones intermedios o interfaldas.

La nueva célula de paletizado ha supuesto un notable aumento de la productividad de la empresa, a la vez que ha conseguido unificar el paletizado de las 3 líneas de producción existentes.

Deja tu comentario