¿Qué nos distingue?

Que usted no tiene que preocuparse de nada. Y eso significa tiempo y tranquilidad.

Si está pensando en automatizar su final de línea, confíe en nosotros. Nos ocuparemos de todo y sabiendo lo que hacemos. Éste es el principal motivo, pero hay muchas otras razones que nos distinguen de los demás.

INGETECH ROBOTICS le ofrece:

· «KNOW HOW»

· INSTALACIÓN EN TIEMPO RECORD.

· LIBRE ELECCIÓN DE LA MARCA DE ROBOT.

· MÍNIMO ESPACIO OCUPADO EN PLANTA.

· MAYOR CAPACIDAD DE PRODUCCIÓN.

· SOLUCIONES ESTÁNDAR DE BAJO COSTE.

SOMOS EXPERTOS EN

MEJORAR FINALES DE LÍNEA

INGETECH ROBOTICS está formado por profesionales con amplia experiencia en el sector de la automatización mediante robots industriales y colaborativos.

Fundada por ingenieros expertos en embalaje y logística, y con un claro objetivo: ofrecer soluciones robóticas de primer nivel para final de línea.

Le ofrecemos:

• CONOCIMIENTO: para optimizar sus procesos productivos.

• EXPERIENCIA: más de 30 años en la industria del final de línea

• GARANTÍA: más de 200 instalaciones realizadas

• SEGURIDAD: cumpliendo la normativa vigente

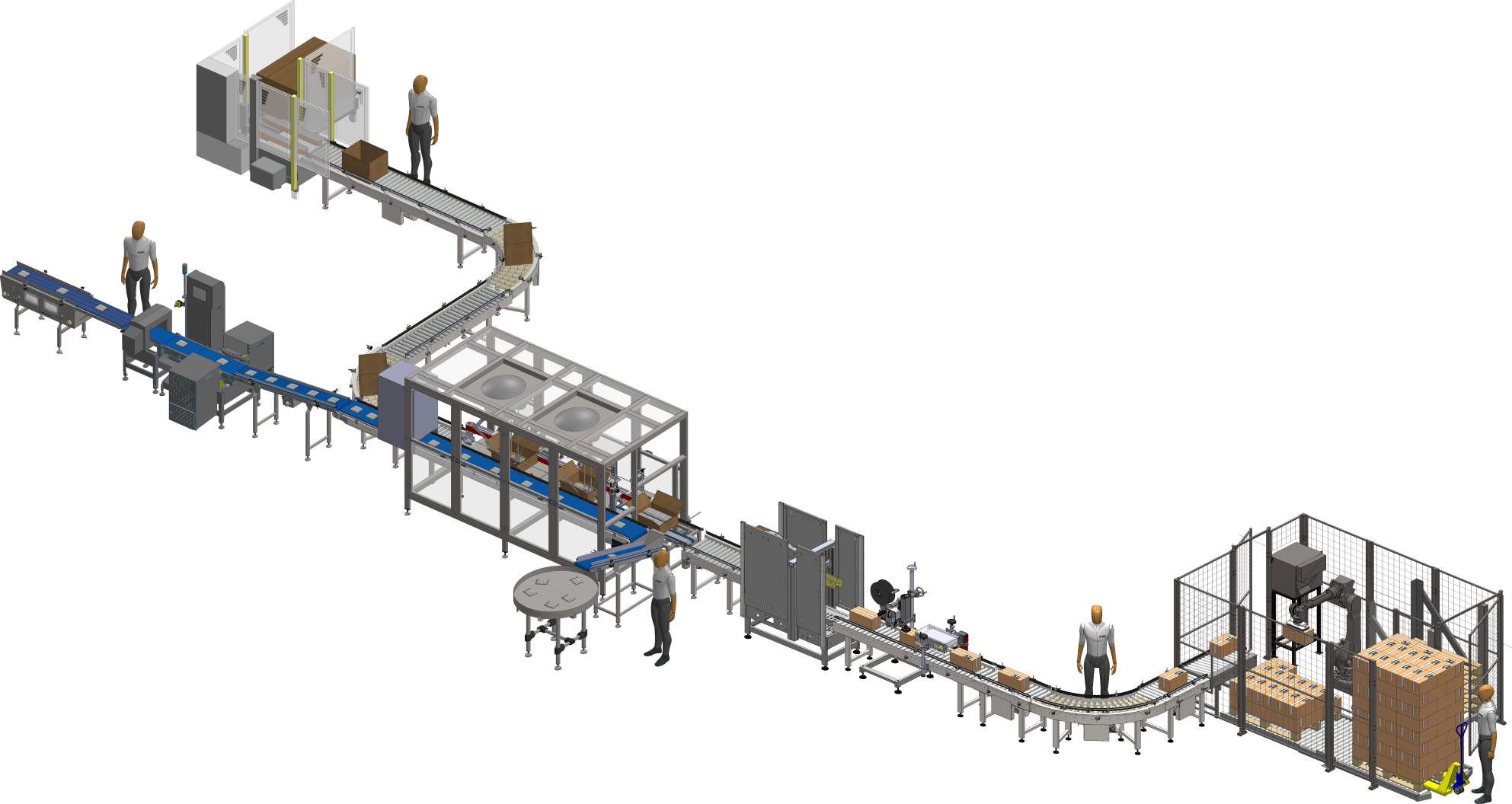

NUESTRO OBJETIVO PRINCIPAL ES DAR SOLUCIÓN A SUS NECESIDADES EN:

INGENIERÍA ROBÓTICA INDUSTRIAL

INGETECH ROBOTICS le ofrece:

- INGENIERÍA DE PROCESOS

- OPTIMIZACIÓN DE TAREAS

- DISEÑO Y SIMULACIÓN 3D

- FABRICACIÓN

- INTEGRACIÓN DE PERIFÉRICOS

- MONTAJE Y PUESTA EN MARCHA

- FORMACIÓN TÉCNICA

- ADAPTACIÓN DE MAQUINARIA A NORMATIVA

- PROGRAMACIÓN (PLCs y ROBOTS)

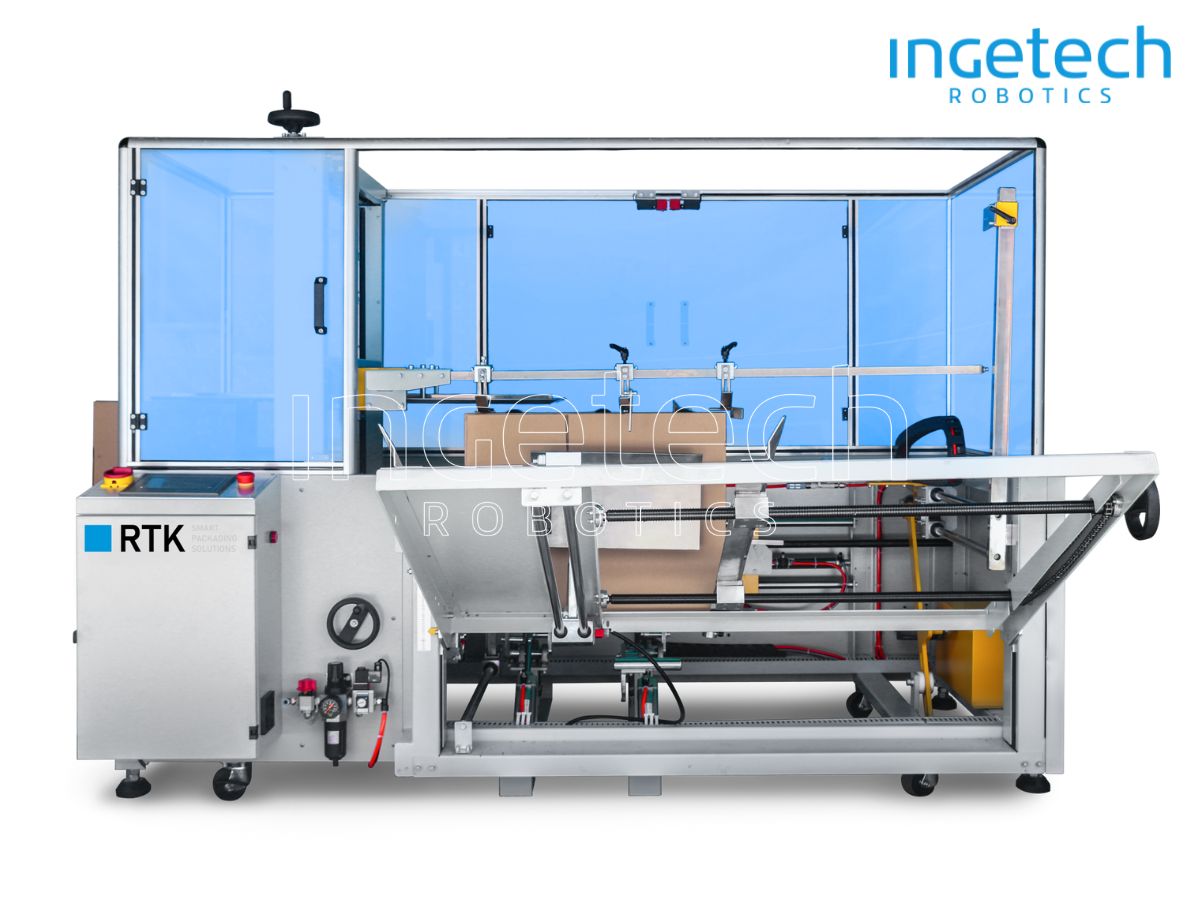

MAQUINARIA DE PACKAGING

Piense en INGETECH si necesita una solución para:

- FORMADO DE CAJAS

- AGRUPACIÓN Y ENCAJADO DE PRODUCTO

- INSPECCIÓN – CONTROL DE CALIDAD

- PESAJE DINÁMICO

- DETECCIÓN DE METALES

- ETIQUETADO, MARCAJE Y CODIFICACIÓN

- GESTIÓN DEL RECHAZO

- PRECINTADO

- ENFARDADO

- PALETIZADO

- GESTIÓN DE PALÉS

Formadora automática de cajas

SISTEMAS DE TRANSPORTE INTERIOR

Piense en INGETECH si necesita una solución para:

- TRANSPORTADORES DE RODILLOS PARA CAJAS

- Transfers, curvas, desviadores, topes, salidas merge, etc.

- TRANSPORTADORES DE RODILLOS PARA PALÉS

- Dispensadores, transp. de cadenas, Mesas de giro, etc.

- SORTERS LOGÍSTICOS

- SISTEMAS DE PREPARACIÓN DE PEDIDOS

- Etc.

Transportador para palés

AUTOMATIZACIÓN DE PROCESOS

AUTOMATIZACIÓN DE PROCESOS

Diseñamos adaptándonos a sus necesidades con la máxima flexibilidad.

Nuestros ingenieros y programadores, analizan su necesidad para ofrecerle la solución que usted realmente necesita.

Nos encargamos del proceso completo, nuestros proyectos son «llaves mano». Tanto en lo referente a la mecánica como a los armarios eléctricos de la instalación incluyendo su fabricación y programación.

También implementamos soluciones 4.0 y actualizamos su instalación («Retrofitting»).

MONTAJE Y PUESTA EN MARCHA

CÉLULAS COMPACTAS

Nuestras células compactas han sido diseñadas con el concepto PLUG & PLAY para un montaje rápido y seguro.

Su instalación no interfiere en su producción. Usted podrá seguir trabajando durante el montaje de la célula, y en 1 sólo día la tendrá instalada. Sólo necesita disponer de una carretilla elevadora para su ubicación. Nada más sencillo y rápido.

Un entorno amigable en las pantallas de operación, le facilitarán asimismo su puesta en marcha de manera que el mismo día estará usted paletizando con su robot.

NUESTRO PROGRAMA DE VENTA

NUESTROS CLIENTES PREGUNTAN…