Si ha considerado automatizar su proceso de encajado, INGETECH ROBOTICS le ofrece una solución eficiente para encajado por robot de manera sencilla, rápida y económica.

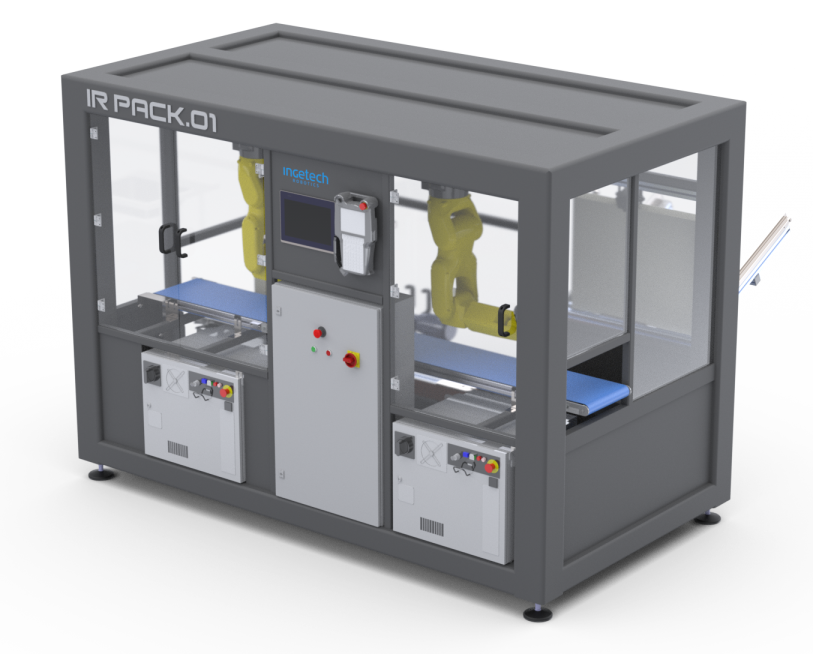

Nuestra célula de encajado IR PACK.01 le brinda la posibilidad de integrar en su línea un sistema de encajado rápido y flexible para un sinfín de productos y tamaños de caja.

Es la hora de instalar un robot industrial para no quedarse atrás. Su competencia ya lo está haciendo y en breve reducirá sus costes de producción siendo más productiva que usted.

Nuestra célula de encajado IR-PACK 01 incorpora los robots industriales más avanzados del mercado, con las mayores ventajas vistas hasta ahora en robótica.

CÉLULAS DE ENCAJADO

«Encajadora automática por robot IR PACK.01. Para diferentes tipos de producto y para producciones de hasta 50 ciclos/min»

¡ AUMENTE SU PRODUCCIÓN DE MANERA EFICIENTE!

¡La solución más versátil y compacta del mercado!

| MAYOR CAPACIDAD DE CARGA | <10Kg/ud (Según robot) |

| MAYOR ALCANCE | <1.100 mm |

| MAYOR VELOCIDAD DE TRABAJO | 50 ciclos/min |

| TIPOS DE ROBOT | Robot Delta o Antropomórfico |

| MAYOR VERSATILIDAD | Robot formador de cajas integrado |

| MAYOR SEGURIDAD | Bastidor compacto con accesos seguros |

| MAYOR PRECISIÓN | Precisión de picking +/-0.01 mm |

| MÍNIMO ESPACIO EN PLANTA | <5 m2 |

>La versatilidad de nuestra máquina le permite el encajado de:

- Blisters

- Packs

- Cajitas

- Botes

- Latas

- Bolsas

- Botellas

- Etc...

No lo dude, contacte con nosotros para saber más sobre nuestra solución.

CÉLULAS DE ENCAJADO CON ROBOT DELTA

ROBOTS

Pick & Place

Instalamos sistemas de posicionado, agrupado, encajado, etc. Sistemas pick & place con robótica de alta velocidad.

Tenemos soluciones estandarizadas para diferentes productos y sectores: alimentación, industria del embotellado, industria conservera, etc.

En comparación con la automatización fija convencional, nuestros sistemas ofrecen mayor flexibilidad con un formato compacto, manteniendo una alta productividad y la altas capacidades de carga.

Nuestras soluciones de picking flexible permiten la integración de diferentes tipos de robots. Nuestras soluciones utilizan tanto sistemas de robot Delta ("Robots Araña") como robots industriales.

Disponemos de variantes con cargas de hasta 20 kg, y un amplio rango de alcances, lo que significa que hay un sistema para casi cada necesidad. Combinando un inmejorable control de movimiento, ciclos cortos y precisión exacta, podemos operar a velocidades muy rápidas en espacios desde muy estrechos a muy anchos y con tolerancias mínimas.

Cada sistema puede incorporar diferentes sistemas de pinzas según el tipo de producto, permitiendo un flujo eficiente de productos a granel o embalados a alta velocidad desde una cinta transportadora.

La incorporación de sistemas de visión artificial, permite el picking en movimiento mediante sistema Line tracking con gran precisión.