SLIDING SHOE SORTERS

DATOS BÁSICOS

Adecuado para artículos difíciles de manipular. Por ejemplo, de forma irregular / Bolsas / Artículos estrechos y largos, etc. Paquetes de distintas medidas y pesos/Sobres/Bolsas/ / etc.

Aplicación en Industrias de comercio electrónico, empresas de paquetería, centros logísticos, pedidos multi-referencia, etc.

TIPO DE PRODUCTOS

Cajas de cartón, bolsas, packs, etc.

DIMENSIONES Máx. de PAQUETE

600 x 1.200 mm

PESO Máx. DEL PRODUCTO

Kg

PRODUCCIÓN MÁXIMA

Ud/hora

SLIDING SHOE SORTER

IR-SSS01

El sistema de clasificación de paquetería SLIDING SHOE SORTER IR-SSS.01 es una solución de alta capacidad.

La extracción se realiza mediante zapatas deslizantes sobre un sistema giro en Loop vertical.

Capaz de funcionar a velocidades de hasta 1.2 metros por minuto, el clasificador puede alcanzar tasas de clasificación de hasta 8.000 piezas por hora. Está diseñado para clasificación con expulsión lateral.

Su tecnología de conmutación electromagnética de alta velocidad, y su mecanismo de funcionamiento silencioso han alcanzado estándares internacionales avanzados. Con una capacidad de clasificación de 8.000 piezas por hora, es la opción preferida por las industrias de comercio electrónico, mensajería y confección para equipos de clasificación inteligente.

Independientemente del peso, tamaño y forma de la mercancía, el exclusivo clasificador de zapata deslizante proporcionará una clasificación precisa, flexible y rápida. El sistema cuenta con una capacidad de conmutación de muy alta velocidad y es adecuado para una amplia gama de aplicaciones de clasificación.

Tecnología de conmutación electromagnética de alta velocidad

La función de velocidad y clasificación se combinan perfectamente mediante la adopción de la última tecnología de conmutación de alta velocidad impulsada electromagnéticamente. La capacidad de conmutación de milisegundos y la tecnología única de eliminación de vibraciones de la horquilla son seguras, confiables y no requieren mantenimiento.

Tasa de clasificación de alta velocidad

El host clasificador puede funcionar a una velocidad de línea operativa de 2,5 m / s. La tasa de clasificación de un solo lado puede alcanzar 8.000 piezas por hora. Los elementos también se pueden clasificar simultáneamente en ambos lados.

Tecnología de integración de unidades modulares

Al utilizar la tecnología de integración de unidades modulares, la construcción es simple y conveniente para el mantenimiento. Quitar y reemplazar una zapata deslizante se puede completar en solo dos minutos.

Ruido bajo

El uso de los últimos materiales de alta tecnología ha reducido el ruido de funcionamiento creando un entorno de trabajo más cómodo. El ruido de funcionamiento de la línea principal es inferior a 70 dB.

Tecnología de accionamiento síncrono de doble motor

El uso de dos motores de accionamiento de tecnología de baja potencia en lugar de un solo motor de gran potencia para impulsar la línea principal proporciona una mayor precisión de control y un sistema más estable y de fácil configuración.

SLIDING SHOE SORTER

DATOS TÉCNICOS

| CAPACIDAD DEL SISTEMA: | <8.000 Ud/hora |

| DIMENSIONES PAQUETE: | S/modelo Máx. A=600 L =1.050 mm |

| PESO PAQUETE : | 0,15-30 Kg |

| VELOCIDAD DE TRANSPORTE: | 0.5-1.2 m/s |

| ANCHO DE TRANSPORTE: | 280 – 440 -540 mm |

| LONGITUD: | Máximo 80 diverters |

| TIPO DE TRANSPORTE: | Platos de aluminio |

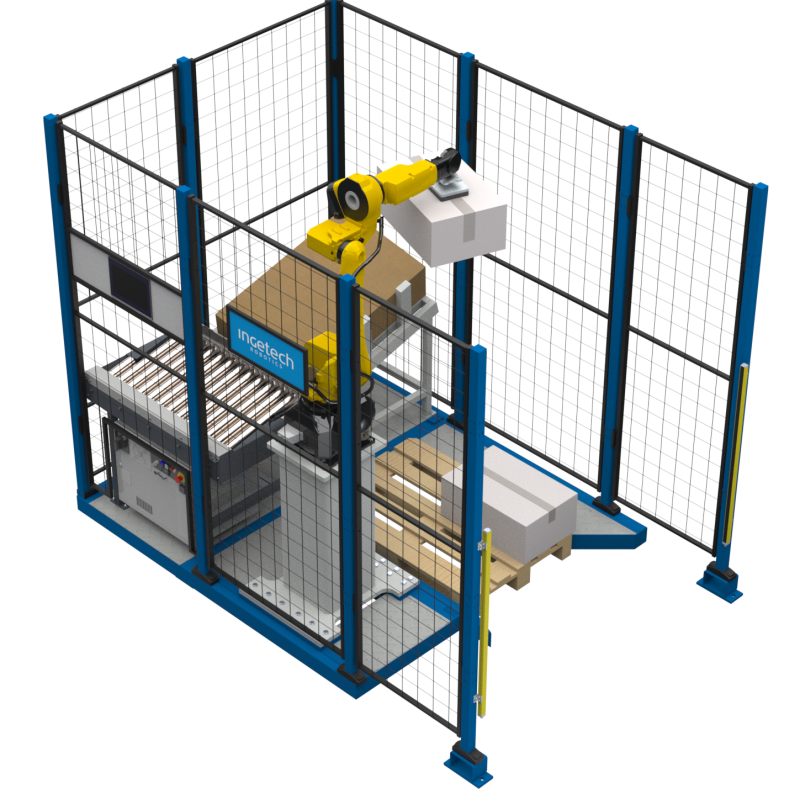

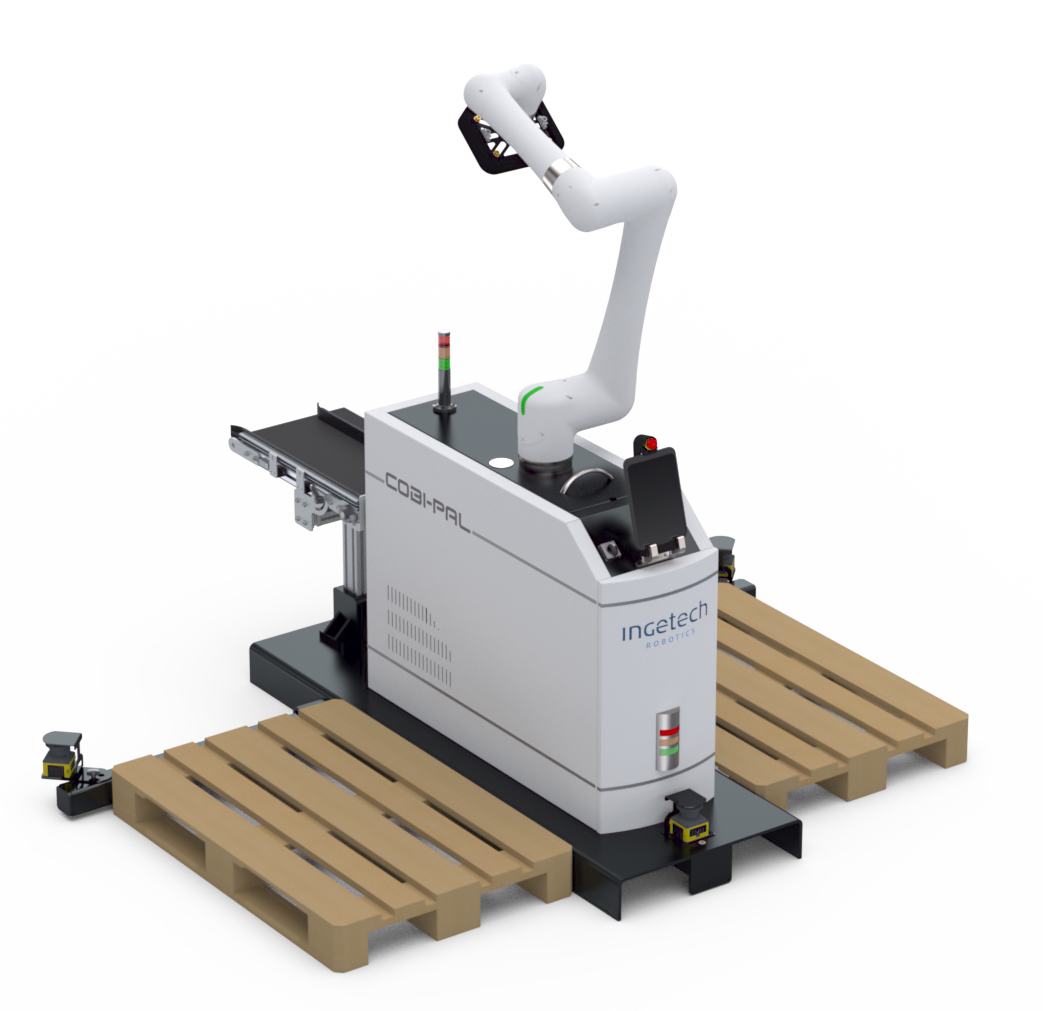

CÉLULAS COMPACTAS DE PALETIZADO

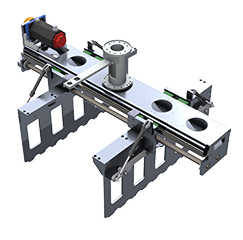

TIPOS DE ROBOTS

ENCAJADO